Portable appliance testing (PAT) is widely accepted as the best way to ensure electrical devices are safe.

But the cost of external testing may leave you wondering, ‘Can I PAT test my own equipment?’

The short answer is yes.

And taking matters into your own hands can save time and resources. But portable appliance testing isn’t as straightforward as it seems.

This blog post explores the essential considerations, skills and legal requirements of PAT testing your equipment. It will help you decide whether in-house testing suits you or your organisation.

What is PAT Testing?

Portable appliance testing is a systematic approach to ensure that electrical devices are safe for use.

A complete PAT test includes two separate procedures: a visual inspection and a series of checks using a portable appliance tester.

Visual inspections involve examining the appliance, plug and cable for any signs of damage. This process requires a keen eye and knowledge of both the appliance and electrical safety. But it doesn’t need any specialist equipment. Visual inspections confirm that the external parts of the appliance are in good condition.

Using a portable appliance tester can confirm that the internal parts of an electrical device are also safe. Conducting these tests requires more in-depth knowledge. You need to understand the appliance and electrical safety, as well as the portable appliance tester itself. You must also be able to interpret its results to confirm whether equipment is safe or not.

Is PAT Testing a Legal Requirement?

You are not legally required to PAT test equipment in your workplace. But you are responsible for ensuring work equipment is safe and electrical risks are suitably controlled.

Several key pieces of UK legislation underscore the need for electrical safety in workplaces:

- The Health and Safety at Work Act of 1974 (HSWA) sets the legal framework for health and safety in the UK. Under the HSWA, all employers must protect employees and the public from harm caused by their work activities

- The Provision and Use of Work Equipment Regulations (PUWER) 1998 requires all equipment provided for use at work to be safe, appropriate and maintained in good working order

- The Electricity at Work Regulations 1989 specifies all electrical systems, including equipment in them, be constructed and maintained to prevent danger

The Electricity at Work Regulations 1989 is most closely associated with portable appliance testing. While PAT is not directly referenced in these regulations, it has become recognised as best practice for achieving compliance and making electrical devices safe at work.

Can I PAT Test My Own Equipment?

Yes, you can PAT test your own equipment. And there are advantages.

Doing it yourself can save considerable time and resources. It also gives you greater control over the maintenance and safety of your equipment.

But it’s crucial to understand the full PAT process, including formal visual inspections and using a portable appliance tester.

We’ve included an overview of each step below to give you an idea of what a full PAT test involves.

Visual Inspections

A visual inspection involves thoroughly examining the appliance for any visible signs of wear, damage or faults. The procedure includes looking at the cable and plug, including its wiring and fuse.

This step doesn’t require specialist equipment but demands attention to detail and a solid understanding of what counts as an electrical hazard. Many professionals find inspection checklists helpful. They can remind you of the critical checkpoints and make it easier to record your findings.

Testing with a Portable Appliance Tester

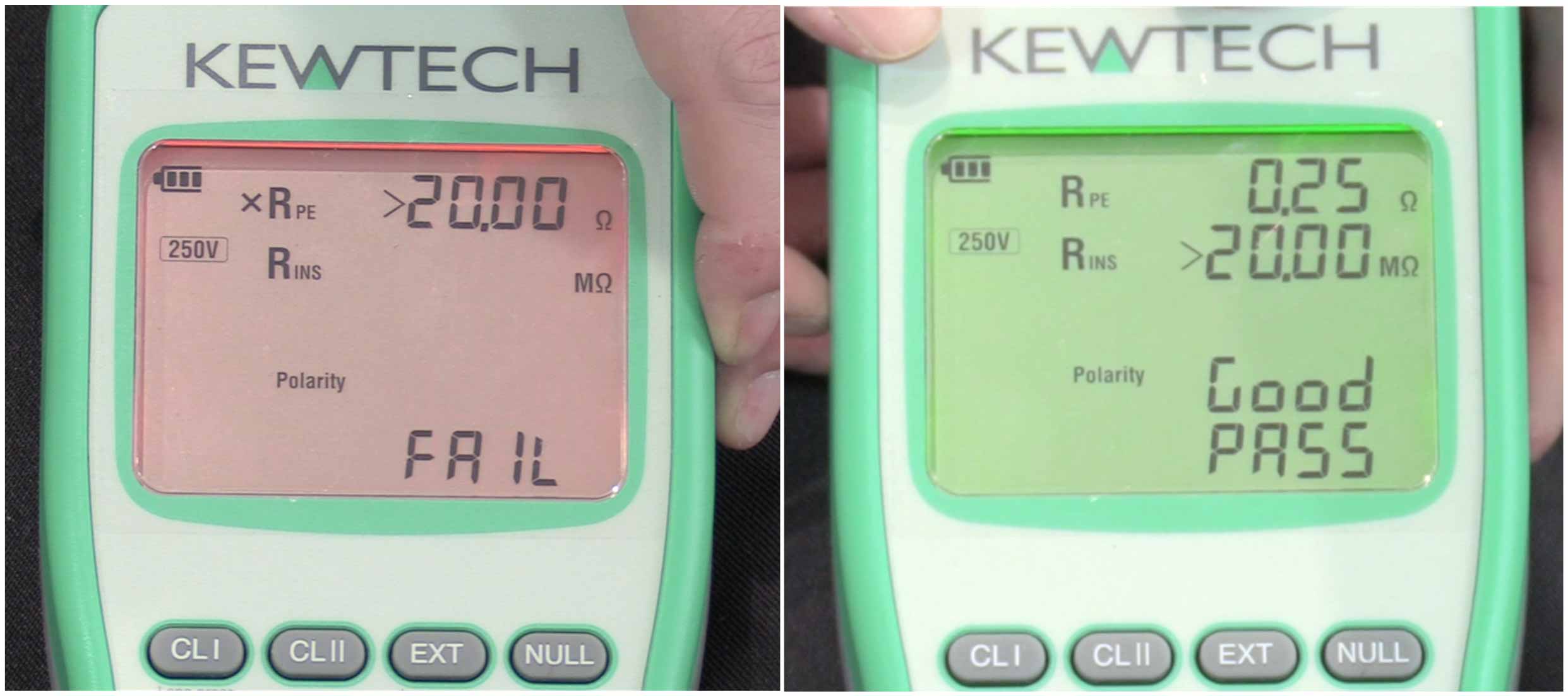

Testing with a portable appliance tester checks the internal safety of the appliance. To confirm an appliance is safe, it must pass multiple tests. Each test evaluates a different aspect of electrical safety.

These tests are:

- Earth Continuity Test: Confirms the appliance’s Earth connection is sound. This test is crucial for Class I appliances

- Insulation Resistance Test: Measures the insulation’s effectiveness in preventing electric shocks

- Lead Polarity Test: Ensures the wiring in plugs and leads is correctly configured

- Earth Leakage Test: Measures the current that may leak from the appliance’s enclosure to the Earth

The Importance of Accurate Interpretation

You must be able to conduct the full range of tests and interpret their results. Failing to identify hazards could lead to accidents and potentially endanger lives.

And you may be held accountable for any harm caused by unsafe equipment you’ve wrongly passed.

Recording PAT Results

Any appliance that has been passed must be labelled accordingly. Labels indicate the appliance is safe to use and when it should be tested again.

It’s also necessary to keep a record of tests and the outcomes. This documentation proves compliance with electrical safety regulations should anything be questioned. It can also help you manage when equipment needs to be tested in the future.

Appliances that fail can’t be used until they’ve been repaired and retested.

Do I Need to PAT Test Every Appliance?

The purpose of PAT testing is to check an appliance is safe to use. Because different appliances have different safety features, doing the full test is not always necessary. It depends on the equipment’s class and risk level.

Electrical appliances are classified into three categories, each requiring different levels of testing. You can find a complete guide on what needs testing here. But we’ve outlined the three classes and what checks they need below.

Class 1 Appliances

Class 1 appliances rely on an Earth connection for safety, making them the highest priority for PAT testing. This class of appliance requires a full test, including both visual inspection and the use of a portable appliance tester.

Common examples include kettles, toasters and some handheld power tools. High-risk environments or frequently used equipment might need more frequent testing.

The symbol for Class 1 is shown below.

Class 2 Appliances

Class 2 appliances are double insulated and don’t require an Earth connection. The added insulation reduces the risk of electric shocks, so they don’t need the same level of testing as Class 1 appliances. Regular visual inspections and the use of a PAT device to check insulation and leakage are usually enough to pass Class 2 appliances as safe.

Examples include electric drills, photocopiers and lamps.

The symbol for Class 2 is a square inside of another square, shown below.

Class 3 Appliances

Class 3 appliances are the safest category. They operate at a very low voltage, so are not subject to PAT testing in the traditional sense.

Instead, checks should focus on the charger or power supply rather than the device itself.

Examples include laptop chargers, digital cameras and low-voltage desk lamps.

The symbol for Class 3 appliances is a Roman numeral three or the letters “III”.

Non-Portable Equipment

Despite the name, it’s crucial to remember that the need for testing isn’t limited to portable appliances.

Stationary, fixed and IT equipment also require regular checks to ensure they remain safe.

Do I need to PAT Test Employees’ Personal Equipment?

PUWER makes it a legal requirement to ensure the safety of all work equipment, whether privately owned or not.

So yes, PAT testing is necessary if employees use their personal equipment at work.

Do I Need a PAT Testing Qualification?

Given the complexities and stakes of PAT, most people assume some form of qualification is needed to test equipment.

But a formal qualification is not necessary.

What is necessary is an appropriate level of knowledge and skill. Testing itself is hazardous if you don’t understand the procedure. And any employee or member of the public is at risk using your tested appliances if you make a mistake.

Training is the most direct and efficient route to becoming proficient in PAT.

Where Can I Learn to Conduct PAT Tests?

Training to conduct PAT tests is a proactive step in safeguarding your business, employees and customers. Performing your own tests also gives you greater control over the safety and reliability of your electrical equipment. And despite initial training costs, in-house testing often leads to long-term savings.

Our online PAT Testing course provides everything you need to know about portable appliance testing. It walks you through every step of PAT testing and pass/fail criteria with clear visual demonstrations.

Plus, it includes an e-Checklist to streamline your inspections and record-keeping, making compliance and safety management more straightforward.

Start making your business safer today. Sign up for our PAT testing course and develop the knowledge to conduct your own tests.