A wide range of tools utilise so-called abrasive products to perform cutting, grinding and sanding operations. A very common format is a rotating abrasive wheel, which can be used on both handheld and bench-mounted tools.

Although a common piece of equipment across the UK, abrasive wheels can pose significant health hazards and are a leading cause of injury in the workplace.

Due to the risk, there are various abrasive wheels regulations that place legal duties on employers. A failure to comply can result in significant fines for breaches in the law.

Any employer that requires their employees to make use of abrasive wheels should be aware of the relevant legislation and regulations. This article discusses the design characteristics of abrasive wheels and looks at the current abrasive wheels regulations in the UK. We also discuss the importance of abrasive wheels training and show you where you can find accredited online courses for your staff.

The Characteristics of Abrasive Wheels

An abrasive wheel is “a wheel consisting of abrasive particles bonded together with various substances” as per the current definition from the Health and Safety Executive (HSE).

Abrasive wheels can be bonded using inorganic or organic substances.

Inorganic bonding materials are usually the result of firing the wheel in a furnace to give it a strong and hard form. This also adds brittleness to the overall structure. These are known as vitrified inorganic abrasive wheels and are usually used for precision grinding work.

Organic bonds do not use the firing method but are made using bonding agents such as resinoid, rubber and shellac. These abrasive wheels are highly durable and shock resistant. They are most commonly used in cutting work that does not require a degree of precision.

In general, abrasive wheels are used for grinding, cutting, sanding and polishing materials such as wood, tile, concrete and metal. Abrasive wheels consist of a spinning wheel, cone or cup, coated with abrasive articles. They are also known as grinders or cutting wheels.

The Risks of Using Abrasive Wheels

More than half of all accidents resulting from the use of an abrasive wheel occur because of operator error or unsafe working conditions, as reported by the HSE.

Due to the high intensity and power of the spinning wheel, abrasive wheels are hazardous to both operators and people in the near vicinity.

Accidents can occur by coming into contact with the wheel itself, the material being worked on, or by flying debris. Abrasive wheels are prone to breakages that result in pieces of the wheel being ejected at high speeds.

Common causes of abrasive wheel breakages are:

- Improper storage methods

- Wrong wheel selection

- Incorrect mounting

- Extreme out-of-balance conditions

- Undue speed

- Equipment defects

- Incorrect grinding or cutting procedures

More than one of these factors can occur at the same time to cause wheel breakage.

Abrasive wheel operators are also exposed to the hazard of vibration, which can lead to hand arm vibration syndrome (HAVS). HAVS can be permanently debilitating.

There are also risks associated with being in the vicinity of someone using abrasive wheels. Abrasive wheels with high noise levels can cause damage to hearing. The dust given off by working with abrasive wheels can cause lung damage.

Employers can eliminate or mitigate these risks by adhering to abrasive wheels regulations and ensuring that their workers receive adequate training.

Let’s consider the legislation designed to help control for these risks.

Abrasive Wheel Legislation

The Provision and Use of Work Equipment Regulations Act 1998 (PUWER)

The use of abrasive wheels in Scotland, England and Wales is regulated by the Provision and Use of Work Equipment Regulations act 1998 (PUWER). These regulations replaced the previous 1992 PUWER regulations which in turn were introduced to replace the Abrasive Wheels Regulations 1970. PUWER is overseen and enforced by the HSE.

PUWER requires that employers supply only work equipment, such as abrasive wheels, that is suitable and fit for purpose. All tools and machinery must also be correctly installed and not be in a deteriorating condition.

The HSE abrasive wheels PUWER regulations require that abrasive wheels are kept in good condition and are safe to use. All machinery and tools that contain abrasive wheels must be regularly maintained and inspected by a competent, trained individual.

PUWER stipulates that all operators must have undertaken sufficient training in the use of abrasive wheels and be supplied with adequate protective clothing. The workplace must have adequate health and safety measures, including guarding, emergency stop mechanisms, warning devices, visible markings and means of isolation from energy sources.

Please note that in Ireland the use of abrasive wheels is controlled by the Abrasive Wheels Regulations 2016. These regulations cover much of the same ground as abrasive wheels regulations UK or PUWER.

Other Relevant Abrasive Wheels Regulations in the UK

PUWER itself does not deal with all hazards arising from the use of abrasive wheels. Risks from vibrations to the arms and hands, dust and noise are not covered by the guidelines as stated in PUWER. However, there are other pieces of legislation that support the abrasive wheels regulations outlined in PUWER. This legislation includes:

- Health and Safety at Work etc Act 1974 – This is the main piece of legislation that covers health and safety at work in the UK. PUWER 98 relates to all workplaces and work situations that are covered by the Health and Safety at Work etc Act 1974

- The Personal Protective Equipment Regulations 1992 – These regulations mandate that employers must provide adequate personal protective equipment (PPE) to employees

- Control of Substances Hazardous to Health Regulations (COSHH) – COSHH regulations outline what employers must do to control substances that are hazardous to health

- Control of Noise at Work Regulations 2002 – This legislation is designed to ensure that workers’ hearing is protected from high levels of noise in the workplace

Legal Requirements for Manufacturers of Abrasive Wheels

Those who manufacturer abrasive wheels also have legal duties placed on them, under the Health and Safety Act 1974 and the Supply of Machinery (Safety) Regulations 2008. This legislation requires that equipment is only supplied that has been tested as safe under the specific conditions it is intended to be used in.

A declaration of conformity and CE marking, or UKCA or equivalent, must also be affixed to the product as a confirmation of this.

Safe Design

Some of the types of safe design principles that manufacturer’s use in abrasive wheels, include:

-

- Fibre reinforcement – Organic wheels are reinforced with a woven, resin-coated mat made of glass-fibres. This helps the wheel to withstand high stress work and acts to contain fragments if breakage occurs

- Steel rings – These rings are moulded into an abrasive wheel near the bore. They are designed to stop excessive wear and to contain fragments should breakage occur

- Safety inserts – Threaded nuts with locking teeth are part of the plate of an abrasive wheel and act to help strengthen cup wheels used for portable grinding work. Safety inserts are an additional measure. They do not replace the need for a safety guard

- Tape winding – Glass-fibre, adhesive tape or metallic wire can be used to provide extra strength to thin-walled cylinder and cup abrasive wheels

- Fine grit centres – Fine grit centres are placed around the bore of a wheel to increase its strength

Markings on Abrasive Wheels

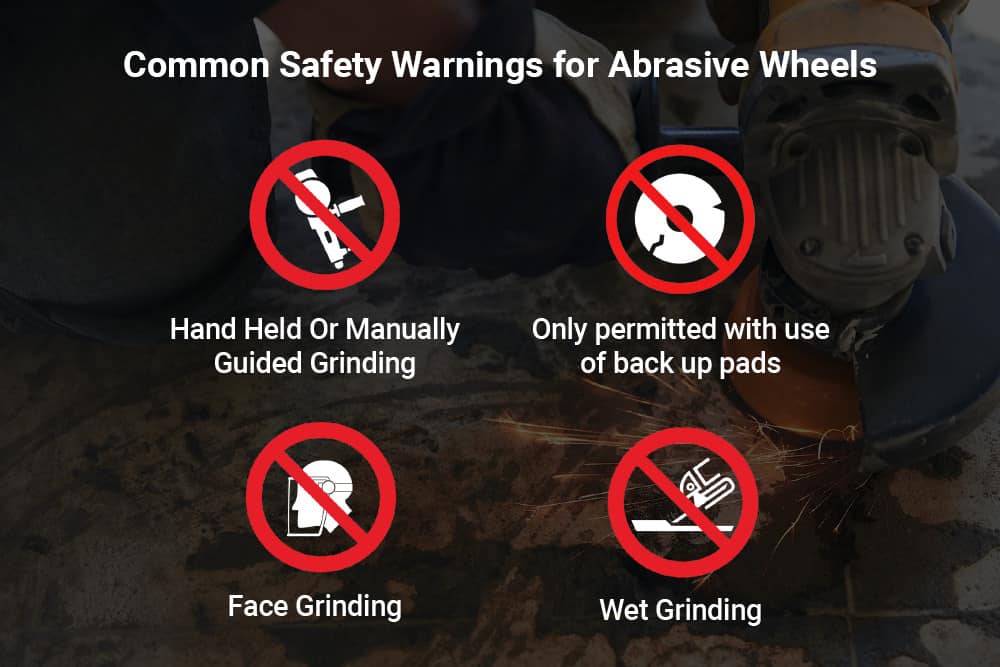

A key risk control for manufacturer’s is the provision of information about how their equipment should be used – what conditions it is safe to be operated in. As such, abrasive wheels must contain markings that conform to the British Standards BS EN 12413 and BS ISO 525.

The markings must include information such as:

- The maximum speed of the wheel

- The restrictions of use

- The shelf life of the wheel

- Traceable manufacturing numbers

- The dimensions of the wheel

- The wheel’s test record number

- The manufacturer’s trademark

- The ISO type number

- Mounting instructions

Meeting Employer Duties

So, in order to meet their legal duty to supply safe and suitable work equipment to their staff, employers must ensure any abrasive wheels that they supply come with declaration of conformity, ensuring they are safely designed, and appropriately marked.

Employers must also ensure that the wheels are only used within the design specifications of the equipment, and only used for the purposes that they were intended.

But this alone is not enough. Employers must also conduct a risk assessment to ensure the work environment and work being done will be conducted safely. Any hazards identified must be suitably controlled.

Any employees using abrasive wheels must be provided with sufficient training to help ensure they are competent to do their jobs safely.

The Importance of Abrasive Wheels Training

To quote the HSE: “There is no substitute for thorough practical training in all aspects of the mounting and use of abrasive wheels”. Abrasive wheels training should provide trainees with information on the risks of using abrasive wheels, what PPE should be worn and what safe work practices are relating to abrasive wheels.

PUWER requires that abrasive wheels training courses explain how to read the markings on abrasive wheels and how to handle, store and transport them. Participants in these courses are required to learn all the functions of common components used with abrasive wheels, such as nuts, bushes, flanges and blotters. Trainees are also taught how to assemble abrasive wheels and how to inspect them for damage.

Human Focus provides online abrasive wheel training that is in accordance with all PUWER or abrasive wheels regulations UK. This training gives participants a solid grounding in the safe use of abrasive wheels. Training can be taken in online bite-size sessions at your convenience. The Human Focus abrasive wheels training course is approved by the International Institute of Risk & Safety Management (IIRSM).