It’s easier than you might think to seriously injure yourself when moving a load. Lifting boxes, equipment or even office supplies can all result in sprains, strains or worse. So, knowing the correct manual handling techniques is essential to protecting you and your staff. It’s also a legal duty.

Health and safety legislation places a specific duty on employers to control the risks associated with manual handling tasks. To help you meet your obligations, we’ve put together a list of the 10 best manual handling techniques for lifting and moving heavy loads at work.

Ten Manual Handling Techniques You Need to Know

Manual handling techniques and procedures can vary according to the workplace and the nature of the work itself. Manual handling techniques for carers are different than for factory workers, for example. However, there are some general rules around good manual handling techniques that should always be followed.

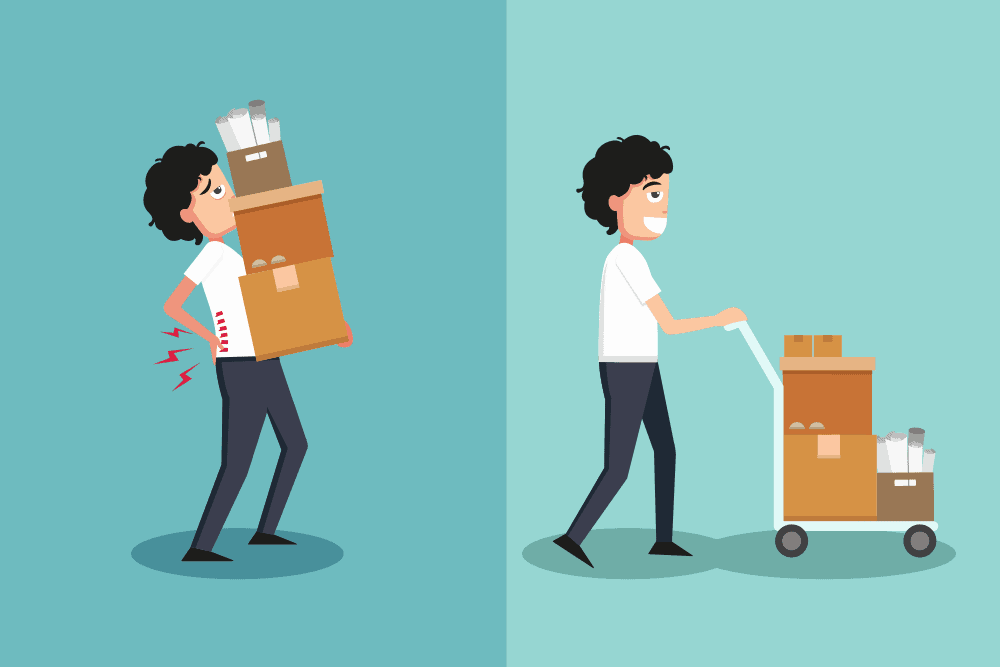

#1 Avoid Manual Handling Tasks If Possible

The first duty that employers have under the Manual Handling Operations Regulations 1992 is to avoid manual handling tasks ‘so far as is reasonably practicable’.

So, when manual handling is being considered, you should first consider if there is an alternative to lifting the load through bodily force. For example, can you automate the process so lifting isn’t required?

#2 Use Lifting Equipment

If there is no other option, it may be safer to use a mechanical lifting aid instead of relying on your strength. Lifting aids include equipment such as lifts, jacks, trolleys and barrows. Anytime you ask staff to use lifting equipment, make sure you supply equipment that’s in proper condition, and that your employees have been trained on how to use it.

#3 Plan Your Lift Carefully

It’s important to carefully plan your lift before attempting it. Be sure that the object is stable, that the route you plan to take is free of obstructions, and that the load is not too heavy for you to carry. If possible, ask someone to help you move the load.

The Health and Safety Executive recommends doing a TILE assessment, which includes considering the Task, Individual lifting, the Load and the Environment that it will be lifted in.

#4 Be Sure of Your Footing

Before you begin the lift, make sure you have a stable footing. Keep your feet apart to give yourself a steady base. If you can, put your dominant leg forward in the direction you will be carrying the load. If you need to adjust your feet during the lift to keep your balance, do so carefully.

#5 Get a Good Grip

Get a good, firm grip on the load before attempting to move it. Keep your arms within the boundaries created by your legs. Use a hooked grip rather than keeping your fingers straight. Wear gloves to protect your hands if they are available. If you need to alter your grip while carrying the load, do so carefully or set the load down first.

#6 Use Your Knees, Not Your Back

Good posture is crucial when lifting heavy objects. Half bend at the knees and bend your back slightly to adopt a semi-squatting posture. Use your upper leg muscles to power your lift instead of your back muscles.

#7 Don’t Twist When Lifting

Begin your lifting using a smooth motion without jerking or twisting. Keep your shoulders aligned and facing the same direction as your hips as you lift.

#8 Keep the Load Close to Your Body

Once you have lifted the load, keep it close to your body. Position the heaviest part of the object close to you, if you can. This will help you keep a tighter grip while carrying the load. Once you are carrying the load, keep your head forward and look straight ahead.

#9 Rest If You Have To

If you are carrying a load over a long distance, try and set it down so you can rest and adjust your grip. It is advisable to put the load down at hip height on a table or bench rather than putting it down on the floor.

#10 Put the Load Down Carefully and Push into Place

When you have reached the area where the load is to be placed, put it down carefully using a smooth motion without sudden movements. Again, avoid twisting or jerking while lowering the load. If the load must be put into a certain position, put it down and then push it where it needs to go.

What Are Manual Handling Duties?

The Manual Handling Operations Regulations 1992 define manual handling as “any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or by bodily force”. A ‘load’ can be any type of object, or it could be a person or an animal.

Under these regulations, all employers and employees must take-action to avoid manual handling risks and prevent accidents and injuries.

Your Manual Handling Responsibilities Under the Law

The law stipulates that employers must avoid the need for manual handling tasks, if at all possible. If the task cannot be avoided, the employer, or a representative, must conduct a risk assessment. All identified risks need to be eliminated or mitigated before the task can be attempted.

Employees are obligated to comply with all manual handling work processes. This includes using correct manual handling techniques, wearing personal protective equipment (PPE) and making use of any lifting equipment supplied. Every employee must not act in a manner that endangers themselves, their colleagues or the general public.

If your team is using unsafe manual handling techniques, then you are at risk of being in breach of health and safety regulations. Breaches are punishable with unlimited fines or criminal charges. The best way to protect your team against injuries and ensure that you comply with the law is to understand what constitutes good manual handling techniques.

This infographic can be distributed to your team to remind them of safe manual handling techniques.

How Poor Manual Handling Procedures Can Impact Your Business

Any business that does not adhere to manual handling regulations faces severe consequences. In 2016, automotive parts manufacturer MAHLE Powertrain Limited was prosecuted by the Health and Safety Executive for breaching the Manual Handling Operations Regulations 1992.

Between November 2013 and January 2015, six MAHLE workers suffered back injuries that resulted in lengthy absences. One worker was unable to work for nine weeks and was hospitalised for seven days. Other employees also reported back injuries, but since these injuries resulted in absences of less than seven days, they were not reported.

These injuries were sustained because workers were required to regularly lift engine components weighing between 14 and 21 kilograms during their shifts. The HSE was able to prove in Birmingham Crown Court that MAHLE failed to provide adequate training in manual handling techniques. The company was also prosecuted for not providing suitable lifting aids or not providing training for their employees on how to use them. MAHLE also faced charges for failing to undertake manual handling risk assessments.

Ultimately, the court found that MAHLE Powertrain Limited had breached regulation 4(1)(b) of the Manual Handling Operations Regulations 1992. The company was fined £183,340 and had to pay £21,277.10 in additional costs.

Who Needs Training in Good Manual Handling Techniques?

Many occupations require employees to regularly undertake manual handling tasks. Retail employees, construction site workers, factory workers and healthcare workers all routinely perform manual handling. If your work involves this type of work, then you must ensure all of your staff have been provided with accredited training.

This training ensures that staff can lift and move heavy objects without the risk of injury and makes certain that the workplace is compliant with health and safety legislation.

Human Focus provides manual handling training designed for workers in a range of industries. Our manual handling courses teach effective manual handling techniques that can be used by managers, office workers, construction workers and other employees. All courses can be taken online at your convenience and average about half an hour in length. Upon successful completion, trainees will receive a downloadable certificate recognised across the UK. Protect your team and your business.