Electrical safety signs are commonly seen in UK workplaces. Similar to other warning signs, they’re used to alert people to electrical hazards, so they can act accordingly. And they’re required by law if they can make workplaces safer.

If you’re an employer or in control of a property, you decide when and how to use safety signs. Our guide can help. It explains when electrical safety signs are required, what types are available and how to use them effectively.

What are Safety Signs?

Safety signs alert workers to hazards and tell them what to do to avoid harm. Their use is governed by the Health and Safety (Safety Signs and Signals) Regulations 1996 (the Regulations). Safety signs come in a variety of forms, including:

- Signboards

- Colours

- Acoustic signals

- Hand signals

- Verbal warnings

For this guide, we’re focussing on traditional signboards. Signboards offer information or instructions through a combination of shape, colour and a symbol or pictogram.

Safety signs are one method among many for managing workplace risks. It’s important to note that they’re considered a last resort and cannot substitute for more robust risk control methods.

Before deploying safety signs, you must be sure you’ve done everything reasonable to eliminate or reduce risks through more effective measures, such as implementing safe systems of work. You’re only then required to use safety signs if they can further reduce residual risks.

The Five Types of Safety Signs

There are five types of safety signs, each serving a specific purpose. These types are:

- Prohibition Signs: These signs tell workers what they absolutely can’t do. They prohibit certain behaviours that put people in harm’s way. Examples include ‘No Smoking’, ‘Do Not Touch’ and ‘No Entry’ signs.

- Mandatory Signs: These signs tell workers what they absolutely should do to protect themselves. These are vital in areas where following safety protocols is essential. Common examples are ‘Wear Ear Protection’, ‘Wear Safety Goggles’ and ‘PPE Must Be Worn’.

- Warning Signs: Warning signs alert workers to danger so they can take necessary precautions. They’re designed to grab attention in areas with potential hazards, such as ‘Danger: Overhead Load’, ‘Flammable Material’ and ‘High Voltage’.

- Safe Condition Signs: These signs guide workers to emergency aid or safety. Examples include ‘Fire Exit’, ‘Emergency Telephone’ and ‘First Aid Station’.

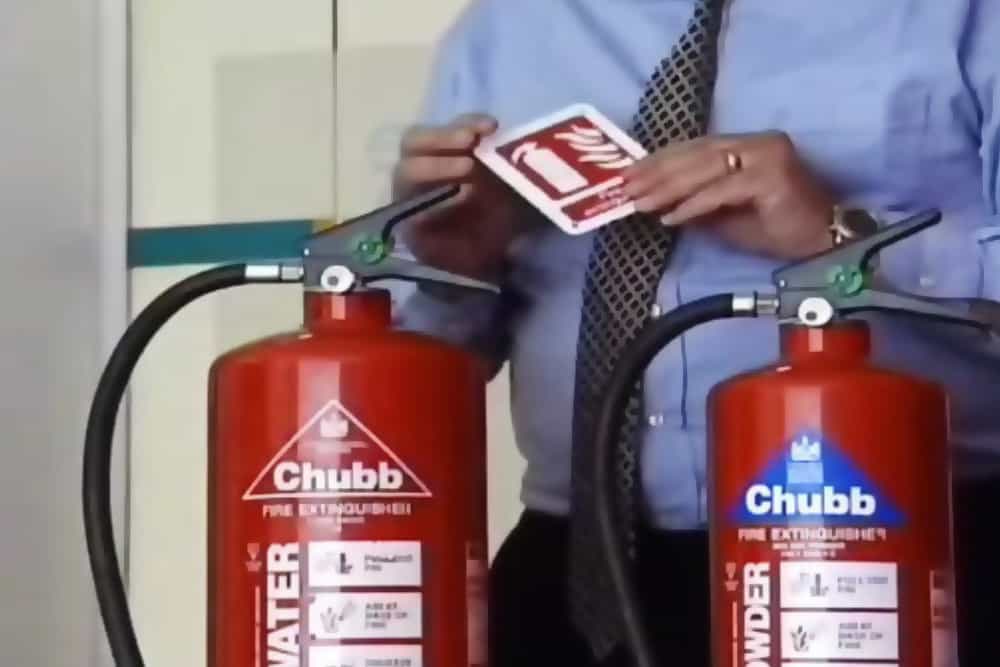

- Firefighting Signs: These signs indicate the location of firefighting equipment. They help individuals quickly identify extinguishers, hoses and alarms, with signs labelled ‘Fire Extinguisher’, ‘Fire Hose’ and ‘Fire Alarm’.

Fire safety signs are an outlier as they’re almost always necessary. Other signs depend on your workplace risk assessment. If they won’t make anyone safer, they’re not required.

What are Electrical Safety Signs?

Electrical safety signs are a category of warning signs designed to alert people to electrical hazards in the workplace. This awareness helps ensure that everyone in the vicinity is aware of the risks and can take appropriate measures to stay safe.

All electrical warning signs share standard design features to ensure they are immediately recognisable and effective in communicating dangers:

- Shape: Electrical warning signs are triangular – a shape applied to all warning signs for fast recognition.

- Colour: These signs have a distinctive yellow background and black border. This stark colour scheme recalls danger and helps signs get spotted. The yellow colour must cover at least 50% of the sign’s area so it’s noticeable from a distance.

- Symbol: A black symbol or pictogram on the yellow background illustrates the type of electrical hazard. Pictograms must be simple to allow for quick understanding without the need for translation.

These characteristics are known as intrinsic features. Intrinsic features are set by the Regulations and guarantee that all safety signs share enough in common to be instantly recognisable and understood by anyone in any work environment.

You can customise safety signs for your workplace, provided you keep the intrinsic features.

What is the Symbol for an Electrical Hazard?

The standard symbol for an electrical hazard is a black lightning bolt on a yellow background. This electrical safety symbol is straightforward and generally understood to signify electrical danger.

Depending on the specific electrical hazard, this symbol might be accompanied by additional text to clarify the nature of the danger, such as “High Voltage” or “Overhead Cables”.

When are Electrical Safety Signs Necessary?

Electrical safety signs can help keep everyone safe at work but are not always necessary. Their use should be based on a careful and thorough risk assessment. If your assessment shows that warning signs can make people safer, they’re required.

You should implement signs in any area where workers might encounter electrical hazards that haven’t been eliminated or sufficiently controlled by other means. These areas include:

- Temporary Worksites: When usual safety setups are disrupted for short periods, signs should be put up to warn people of the new hazards. These situations might include repairs or installations of electrical equipment.

- Electrical Equipment and Circuits: High-voltage electrical equipment and live circuits should be marked with warning signs.

- Hidden Electrical Hazards: Signs can alert workers to less obvious or hidden electrical hazards, such as overhead or buried cables.

These warnings can be combined with other safety signs to make your workplace safer. For example, you might use an electrical hazard warning sign and a ‘No Entry’ prohibition sign together.

There are also mandatory signs related to electricity. Examples include ‘Switch Off When Not In Use’ signs that remind workers to leave electrical equipment in an inert state.

Do Workers Need Instructions on Safety Signs?

Not typically. Safety signs are designed to be as easy to understand as possible, so they all share intrinsic features and simple pictograms.

Most people can understand a warning sign without prior experience. However, it can be helpful to instruct inexperienced workers, particularly if the safety signs in your workplace are unique or uncommon.

Are Electrical Safety Signs Necessary for Visitors?

No. The Regulations only require safety signs for employees.

However, employers have general duties to protect anyone on their premises. Safety signs may help you meet this duty.

PAT Labels

Portable Appliance Testing (PAT) confirms that an electrical appliance is safe to use.

You’re not obligated to PAT test electrical equipment in your workplace. However, doing so is widely accepted as the best way to ensure appliances are safe and comply with the Electricity at Work Regulations 1989. For this reason, PAT is fundamental to electrical safety for most workplaces.

PAT labels show that an electrical device has been tested and is safe to use.

Here’s what you need to know about PAT labels:

- Colour: PAT labels are usually green, which signals the appliance is safe to go ahead and use.

- Information: These labels often show the date of the next test, which helps keep track of when an appliance needs to be checked again.

- Placement: The person who tests the appliance puts on the labels. They ensure the label is visible so everyone can easily see it.

Using PAT labels helps ensure that all electrical equipment in the workplace is safe for use. They’re a simple but effective way to keep track of testing and make sure that everyone knows which appliances are safe to use.

General Advice on Using Electrical Safety Signs

Using electrical safety signs effectively can be key to maintaining a safe work environment. They need to be easy to see and understand, so general guidance says signs should be:

- Visible: Make sure each sign is large enough to be easily seen and read from a distance. They should also be well-lit so that they’re clear even in poor lighting conditions.

- Well Maintained: Regularly check your signs for wear and tear. Faded, dirty or damaged signs are more likely to be overlooked or misunderstood.

- Well Placed: Place signs where they are most needed and where they can be easily seen. Avoid crowding signs together because this will make it harder for workers to notice and process the relevant warning quickly.

- Compliant: Only use signs that have the correct intrinsic features.

Electrical Safety Training

Electrical warning signs can be an effective risk control measure, but they can’t do the job alone. Awareness of a hazard won’t make anyone better off unless they understand electrical safety. That’s why training is so important.

Our online Electrical Safety Training helps ensure everyone understands the risks and knows how to act accordingly around electricity.

The course gives workers awareness of common electrical hazards and explains the corresponding safety measures. Your workers will recognise how they can eliminate or reduce the risk of electrical shocks and accidents, meaning they can act on warning signs correctly and stay safe around electricity.

About the author(s)