There are 5 key principles of manual handling that, when followed, will really reduce the likelihood of injuries. This blog takes a look at each of these principles and aims to provide you with some background knowledge on manual handling so that you can decide how best to prevent incidents in your workplace.

Each day, we do things that require manual handling – we lug heavy shopping bags into the car boot; we lift up our toddlers to put them into a car seat. Often, when taking our dogs for a walk we’re pulled along by them in their eagerness to run off and have fun. Manual handling in some form is unavoidable.

At work we continue to push, pull and carry items – it’s part of the working day. But incorrect manual handling techniques can cause serious musculoskeletal injuries and a host of other disorders.

Why Knowing the 5 Key Principles of Manual Handling is Crucial for Business

A UK based engineering company was fined £20,000 in 2017, after a worker’s fingers were crushed. A manual handling task had gone wrong – a 250 kg metal frame fell while being carried onto the lifter’s hand. Two fingers were partially amputated as a result.

An investigation by the HSE found that this was not an isolated occurrence and that unsafe lifting and maneuvering of the frames was the norm. No risk assessment had been carried out to look at how the operation could be carried out safely or if it could be avoided completely.

The company was found guilty of breaching Regulation 4 (1) (b) of the Manual Handling Regulations.

This kind of incident would be harmful for a business of any size. Along with the fine and life changing injury, incidents like this result in irreparable reputational damage, along with damage to employee morale. It’s not worth taking the gamble and hoping for the best.

What Are the 5 Key Principles of Manual Handling?

An easy way to remember the principles of manual handling is by remembering the 5 Ps – plan, position, pick, proceed and place.

We explore each of the manual handling principles here.

Principle 1 - Plan

It’s vital that you first risk assess the manual handling operation using TILE – a simple acronym that reminds us to assess the Task, Individual , Load and Environment, before conducting a lift. Lack of planning is likely to end in a manual handling disaster.

Start by planning your route:

- Ensure the entire travel path is clear and free from obstructions and hazards from the start of the journey to the end

- Think about who will be handling the item, whether it’s a two-person job or if a crew of people will be needed

Consider the shape and size of the object:

- Is it smooth or awkwardly shaped?

- Does it have handles?

- Does it need to be physically handled or will a mechanical aid like a trolley be best to use?

Lastly, in what environment is the object being handled?

- Will it be moved indoors or outdoors or both?

- Is the ground wet, dry, rough or smooth?

- Is there adequate lighting?

- Is there enough space?

Principle 2 - Position

Position your body and feet correctly before you attempt to handle an object. This will go a long way in preventing an injury.

- Start with your feet roughly shoulder-width apart

- Keep them apart with one leg a little more forward than the other, for support

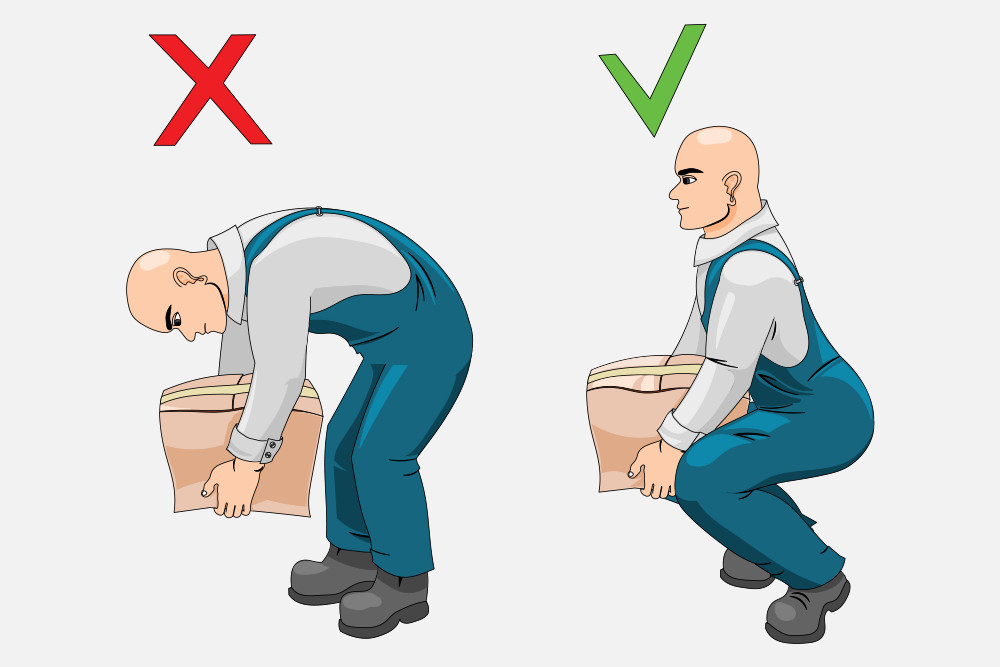

- Bend your knees and avoid bending your back

- Place the centre of your body (torso/core) as close to the centre of the object as possible before lifting it

Make sure you get a good grip of the object. Your hands should be dry and free of debris, a pair of fitted safety gloves may be useful and use any handles that may be on the object.

Principle 3 - Pick

Keeping the load close to your body, engage your core and move upwards at a steady and comfortable pace, using your leg muscles to lift. This will help to give a stable lift. Don’t make any sudden movements while lifting and don’t forget to breath.

Your core muscles should be engaged to stabilize your spine (If you’ve ever taken a Pilates class, this may be very similar to something you have heard the instructor say).

Keep the object in your ‘power zone’ – between mid-chest and mid-thigh. In this area your arms and back can lift heavier items with the least effort.

Principle 4 - Proceed

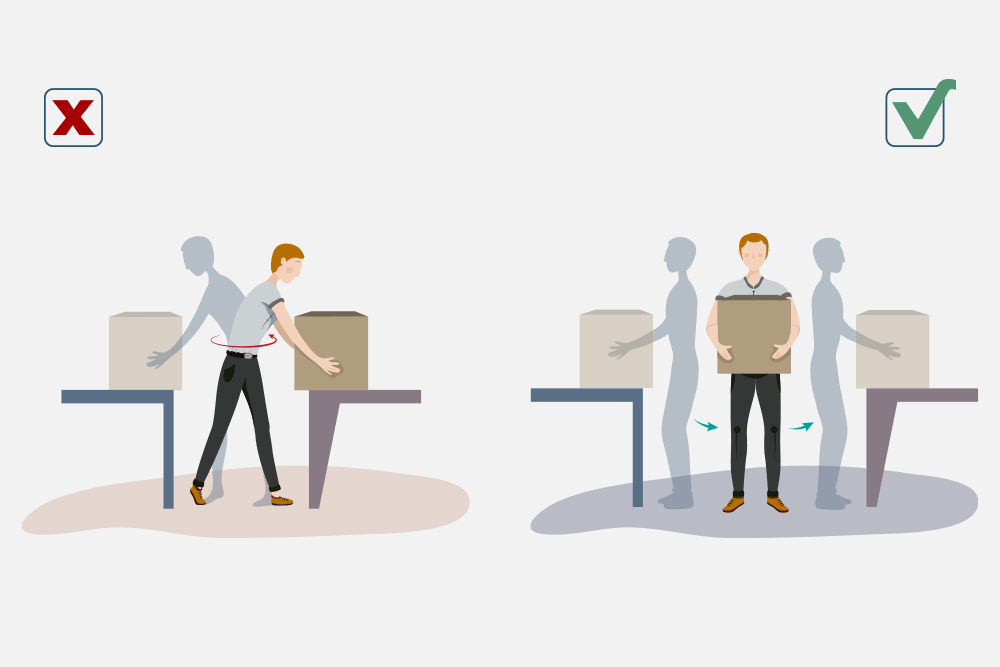

When carrying the load, be sure to keep your spine upright. Avoid bending, twisting and reaching. If you need to turn, do so feet first by stepping in the direction you need to go in, rather than twisting at the waist. The rest of your body will follow through.

Make sure that you have a clear view of where you’re going. Handling a load that’s so big you can’t see over or around it is difficult to maneuver safely. If you don’t have a good view of things, get someone to guide you.

Principle 5 - Place

Now you’re nearing the finish of your manual handling operation. Take care to lower the load slowly, using your knees to avoid bending your back.

It’s tempting to just drop the load but this can cause more harm than good. Not only can it cause an upper body injury, but it can also fall onto your feet. The contents of the item could get damaged too.

Move downwards, steadily and smoothly, and rise up in the same way.

How Can I Learn More About Manual Handling?

The best way to avoid manual handling incidents is to be trained on how to safely handle objects. Start with this free manual handling infographic, which goes through the 5 key principles of manual handling. You can download it to distribute to your team or embed it on your website. Then register for a manual handling course. We have a few to choose from, aimed at a range of industries and workplace environments. Don’t delay because you might regret it. Especially since this kind of training is so affordable – even for the smallest business.