Under UK health and safety law, all employers have a duty to maintain a safe working environment. To safely work with abrasive wheels, you must use the appropriate type of abrasive wheel for a specific job.

Sometimes known as grinding wheels, abrasive wheels often break – even when used correctly. Breakages can cause severe injuries.

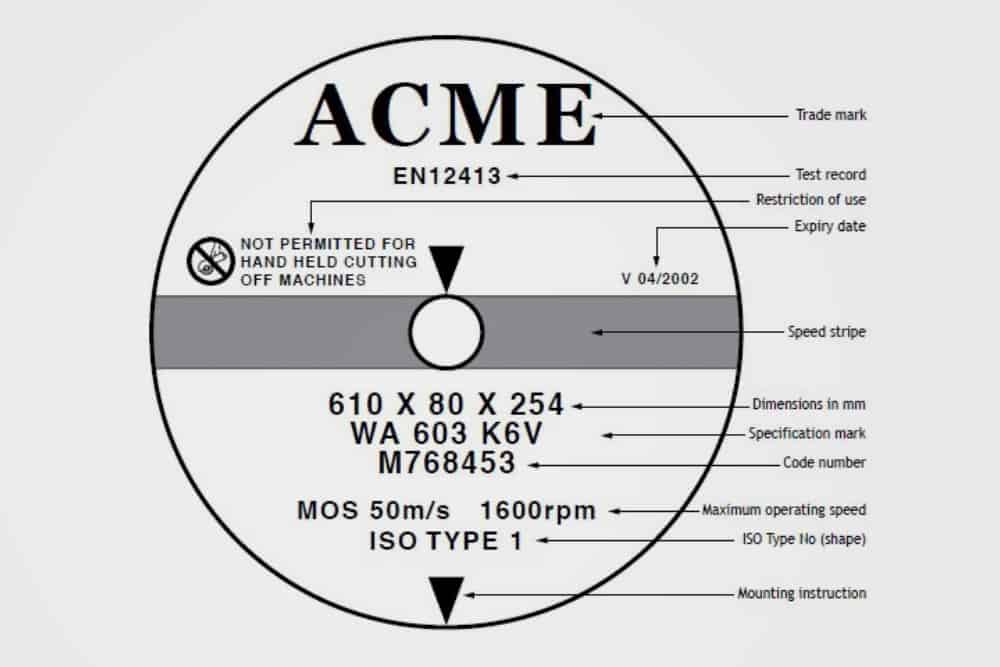

Understanding what abrasive wheel markings mean will help you and your employees to know what type of abrasive wheel to use and reduce the risk of injury. But what exactly does the code number on an abrasive wheel show? In this article, we explain what you need to know about abrasive wheel markings.

Abrasive Wheel Markings Explained

All abrasive wheels must have a series of markings that provide important information on what type of abrasive wheel it is. These markings must be in accordance with the stipulations laid out in the British Standards BS EN 12413 and BS ISO 525.

According to these standards, abrasive wheel markings must contain the following information:

- Manufacturer’s trademark

- Test record to prove that the wheel meets safety standards

- Expiry date (only applicable to organic-bonded abrasive wheels and is usually three years from the manufacturing date)

- A coloured speed stripe that shows the maximum speed of the wheel

- Dimensions of the wheel in millimetres

- Wheel specification mark – a code of numbers and letters that indicate the physical make-up of the wheel

- Traceable code number that gives information on the source and manufacturing aspects of the wheel

- Maximum operating speed

- ISO number that describes the type and shape of the wheel

- Mounting instructions

- Restrictions for use:

- RE1: Not permitted for hand-held and manually guided grinding

- RE2: Not permitted for hand-held cutting-off machines

- RE3: Not suitable for wet grinding

- RE4: Only permitted for totally enclosed working area

- RE6: Not permitted for face grinding

Alongside the maximum operating speed details and the restrictions for use information, abrasive wheel specification markings are of particular importance. Understanding these codes will ensure that an operator knows what type of wheel they are using and how to use it safely.

Key for Abrasive Wheel Code Numbers

Abrasive wheel specification markings are codes that contain both numbers and letters. These codes provide information on what type of material the wheel is made from, how large the grit size is, the grade of the grit, the structure of the wheel and the type of bond.

Abrasive wheel specification codes are made up of a series of sections. The first section will describe the abrasive material.

Common material codes include:

- WA: White aluminium oxide

- A: Regular aluminium oxide

- 19A: A combination of A and WA

- SD: Synthetic diamond

- ASD: Synthetic diamond with metal coating

- FA: Semi-friable aluminium oxide

- PA: Pink aluminium oxide

- SA or HA: Single crystal aluminium oxide

- 23A: A mixture of A and SA

- AZ: Zirconium oxide

- C: Black silicon carbide

- GC: Green silicon carbide

- RC: A mixture of C and GC

The next section will describe the grit size using a number ranging from ten to 1200. Lower numbers indicate coarser grits and higher numbers indicate finer grit size.

Following this section, there will be a letter showing the wheel’s grade. The level of grade is designated from soft to hard alphabetically from A (soft) to Z (hard). A number ranging from one (dense) to 14 (open) will then describe the structure of the wheel.

Lastly, there will be a letter that describes the type of bond used in the wheel. The most typical bond types are as follows:

- B: Resinoid

- V: Vitrified

- R: Rubber

- O: MgO (Magnesium oxide)

- E: Epoxy

- M: Metal

- EP: Electroplated

A commonly used example of an abrasive wheel specification is WA 603 K6V. In this example:

- WA shows that the wheel is made from white aluminium oxide

- 603 describes the grit size

- K shows how hard the wheel is

- 6 denotes the structure

- V shows that it is a vitrified-bonded abrasive wheel

The Impact of Abrasive Wheel Accidents – A Case Study

Accidents involving abrasive wheels can have serious repercussions for the victims, their families, and the companies involved. One example of how damaging an abrasive wheel incident can be was the case of Stuart Stead of Mexborough, Doncaster.

In March of 2012, Mr Stead tragically died after suffering a facial injury caused by flying debris from a broken abrasive wheel in a hand-held grinding machine. An investigation into the incident by the HSE determined that the abrasive wheel exploded as Mr Stead was working. Fragments from the explosion were found up to ten metres from Mr Stead’s work area.

Although Mr Stead was wearing a visor, the grinding machine was not equipped with a guard. When the abrasive wheel failed, a shard from the explosion travelled through the visor and killed Mr Stead almost instantly. The excessive speed of the grinder and the addition of a non-standard attachment caused the wheel to go beyond its capacity and was found to be the cause of the accident.

Mr Stead’s employer, H.I. Quality Steel Castings, was formally charged in Sheffield Crown Court on the 11th of May 2012. The court heard that the HSE investigation had discovered several past incidents where abrasive wheels had broken when used with grinders at the company. None of these incidents was reported or documented in the company’s health and safety meetings.

The HSE alleged that H.I. Quality Steel Castings allowed employees to use unsafe attachments with grinders and did not equip all grinders with guards. Employees were not provided with sufficient abrasive wheel training and so did not fully understand the importance of the rotation speeds of machines in relation to abrasive wheels. H.I. Quality Steel Castings was also accused of failing to properly monitor the use of abrasive wheels and grinders. Several near-miss incidents were not properly investigated.

H.I. Quality Steel Castings was found to have breached section 2(1) of the Health and Safety at Work etc. Act 1974. The company was forced to pay a fine of £150,000 as well as £24,000 in costs. HSE inspector Jill Thompson was reported as saying: “This was a horrific incident that devastated Mr Stead’s wife, his children and wider family. It is also, tragically, one that could have been avoided had the company focused on its responsibility to ensure the safety of their employees.”

Where You Can Find Accredited Abrasive Wheels Training

As illustrated in the case study above, using the wrong type of abrasive wheel can result in serious injuries or death. It is critical that all operators make sure they are using the appropriate type of abrasive wheel for the task at hand.

Choosing the right abrasive wheel for the job means knowing exactly what the code numbers and markings on the wheel stand for. Operators must also know how to set up, use, inspect, and maintain tools and machinery that contain abrasive wheels.

Completing an Abrasive Wheel Training course from Human Focus will give your staff the knowledge they need to use abrasive wheels safely. Enrolling your employees for this training will also ensure your business stays within the law.

The Abrasive Wheel training course can be taken in segments online at your convenience. Upon successful completion, trainees will be able to download a printable certificate recognised and approved by the International Institute of Risk & Safety Management (iiRSM).

Explore the full range of health and safety courses at Human Focus and start creating a safer workplace today!