Portable appliance testing (PAT testing) is widely accepted as best practice in most industries. It’s a simple way for employers to ensure workplace electrical equipment is safe and maintained in good working order.

And because PAT testing can be done by any competent person, many companies keep it in-house. Training employees is often more cost-effective than hiring external PAT testers and gives employers more control over the process.

But even in-house PAT testing costs time and money. If you keep it within your company, you should know what needs PAT testing.

Otherwise, you may waste time testing appliances unnecessarily. Or worse, letting potentially hazardous appliances sit unchecked.

This guide explains exactly what needs PAT testing so you can be confident you’re fulfilling your obligations and keeping your workplace safe.

Do I Need to PAT Test?

You should PAT test an electrical appliance if it uses a flexible cable or a plug and socket. It’s important to note the word ‘should’ here.

PAT testing itself is not a legal requirement. Technically, you don’t have to PAT test any electrical equipment in the workplace. But you better have an equally effective method of ensuring appliances are safe because there’s a range of electrical safety obligations on employers.

The Health and Safety at Work etc. Act 1974 states all employers must provide a safe working environment. This legislation has implications for various health and safety issues, including electrical safety.

The Electricity at Work Regulations 1989 is more specific. These regulations demand all electrical systems are suitably maintained. This obligation is bolstered by the Provisions and Use of Work Regulations 1998 (delightfully referred to as PUWER). PUWER states every employer must ensure work equipment is maintained in:

- An efficient state

- Efficient working order

- Good repair

All of these obligations exist to make workplaces safer. And with around a quarter of all workplace fires in the UK started by faulty electrical equipment, you have a moral and legal duty to keep appliances safe.

PAT testing is one of the most effective ways to do this.

What Is a PAT Test?

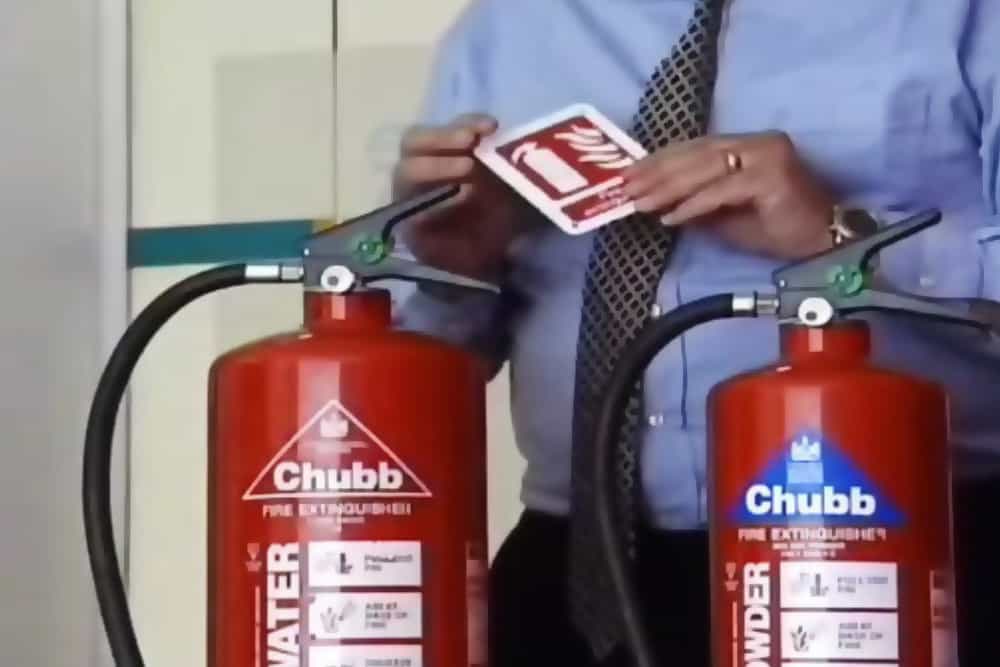

A PAT test involves two steps:

- A formal visual inspection

- A test using a portable appliance tester

User checks are also often mentioned when discussing electrical safety measures but they aren’t technically part of the PAT process. A user check is a basic visual assessment that everyone should do before using any electrical device in the workplace.

Visual inspections are more thorough and should be recorded. They look for signs of damage or potential faults and should only be conducted by competent people.

Tests with a portable appliance tester should also only be conducted by competent people. They incorporate multiple assessments: An Earth continuity test, an insulation test and a leakage test. Combined with a visual inspection, all three make up a full PAT test.

What Needs to be PAT Tested?

Employers must ensure all appliances in the workplace are safe.

But the Health and Safety Executive (HSE) doesn’t recommend full PAT tests for every type of electrical equipment. And there will likely be devices in your workplace that only require visual inspections or user checks.

It all depends on the class of the appliance.

Class 1

A Class 1 appliance has basic insulation and is most likely to cause harm.

Every Class 1 appliance has three wires in the plug: Live (brown), Neutral (blue) and Earth (green and yellow). The Live wire carries the voltage; the Neutral wire carries the voltage back to the source; and the Earth wire gives electricity a safe route to the ground if the equipment malfunctions.

Typical Class 1 appliances include kettles, toasters, fridges – basically your whole kitchen. Certain handheld power tools are also Class 1, as are extension leads and IEC leads (also known as kettle leads).

The HSE says you should fully PAT test all Class 1 appliances every one to two years. They should also be visually inspected every six months.

Higher-risk equipment will need more frequent testing. For example, 230-volt construction equipment should be visually inspected weekly and PAT tested monthly.

To identify Class 1 appliances in your workplace, you should look for this symbol:

But it’s not a legal requirement for Class 1 appliances to be marked this way, so you can’t depend on it.

Class 2

All Class 2 appliances have additional insulation. This makes them safer than Class 1 appliances and renders full PAT tests unnecessary.

The added insulation makes Earth wires redundant so you’ll only find Neutral and Live wires in a Class 2 appliance’s plug.

Common appliances like lamps, photocopiers and computers are all Class 2.

The HSE doesn’t recommend full PAT tests for Class 2 appliances. Still they should be subject to regular insulation tests using a portable appliance tester. They should also be visually inspected every one to two years.

Class 2 devices might also be marked by the symbol shown below. But again, it’s not a legal requirement so you can’t always depend on it.

Be aware there’s a risk of damaging Class 2 appliances when checking them with a PAT tester. Ensure whoever is conducting the test is confident and knows what they’re doing.

Class 3

Class 3 appliances are low-voltage and often battery-powered.

Think of devices like mobile phones, torches or digital cameras.

PAT testing for Class 3 appliances is not recommended because their low voltage means they’re unlikely to cause harm. But be aware that some charging cables/devices may count as Class 1 equipment, so will need PAT testing.

What If I Don’t Know the Class of My Appliance?

You should contact the manufacturer if you’re unsure of an appliance’s class.

If this doesn’t help, treating the appliance in question as Class 1 is best. But don’t check the wire to confirm this unless you’re qualified to do so.

Is PAT Testing Only for Portable Appliances?

The ‘P’ in PAT does stand for portable but don’t let that fool you. PAT testing is not only recommended for equipment you can move easily.

Some stationary Class 1 appliances need PAT testing. For example, vending machines, fridges or washing machines.

Do New Appliances Need PAT Testing?

It shouldn’t need PAT testing if you’ve purchased new electrical equipment from a reputable business.

However, it’s still good practice to perform a user check on new equipment. There’s always a chance it’s been damaged in transit or was delivered with a fault.

Do These Recommendations Apply To Every Business?

The recommendations in this guide are general rules. Some workplaces will have more rigorous PAT test requirements.

It all depends on the risk level of your workplace. And the risk level is decided by three key factors:

- The risk level of the equipment

- The type of equipment being used

- Who handles or interacts with the equipment

For example, most offices are considered low-risk. Electrical equipment in these environments is generally only used by trained employees and is rarely moved.

Schools and hospitals would be medium-risk as there’s a higher probability of children or untrained members of the public coming into contact with more specialist equipment.

Construction sites are the perfect example of a high-risk environment. Power tools are regularly used in adverse conditions and moved around constantly. This is why PAT tests are recommended more frequently for construction equipment.

You should undertake a PAT test risk assessment to determine the testing frequency required in your workplace.

Can I PAT Test In-House?

Yes. Companies that operate in low-risk environments can save time and money by moving PAT testing in-house.

You need to ensure the person conducting PAT tests is competent and has sufficient training, experience and knowledge.

You can do this with our online PAT Testing Course. The course gives participants the understanding needed to conduct PAT tests. They’ll know what needs to be PAT tested and how to do it. And with clear visual demonstrations of every step of the process, trainees will be able to confidently inspect and test the common electrical appliances that need it.

About the author(s)