Employers must protect their staff from all work-related risks. Understandably, risks that can cause severe, immediate harm are prioritised, but some common injuries aren’t the result of an accident or single event.

Musculoskeletal disorders (MSDs) are one of these quiet risks. They develop over time, caused by work conditions that often don’t immediately register as unsafe. But the effects of an MSD can be severe – they can cause pain, immobility or even long-term disability. So, as an employer, you have a duty to protect your staff.

This guide explains how to prevent musculoskeletal disorders in the workplace and ensure compliance with health and safety legislation. Workers will be able to carry out their tasks safely and better protect themselves from some of the most subtle yet debilitating strain injuries.

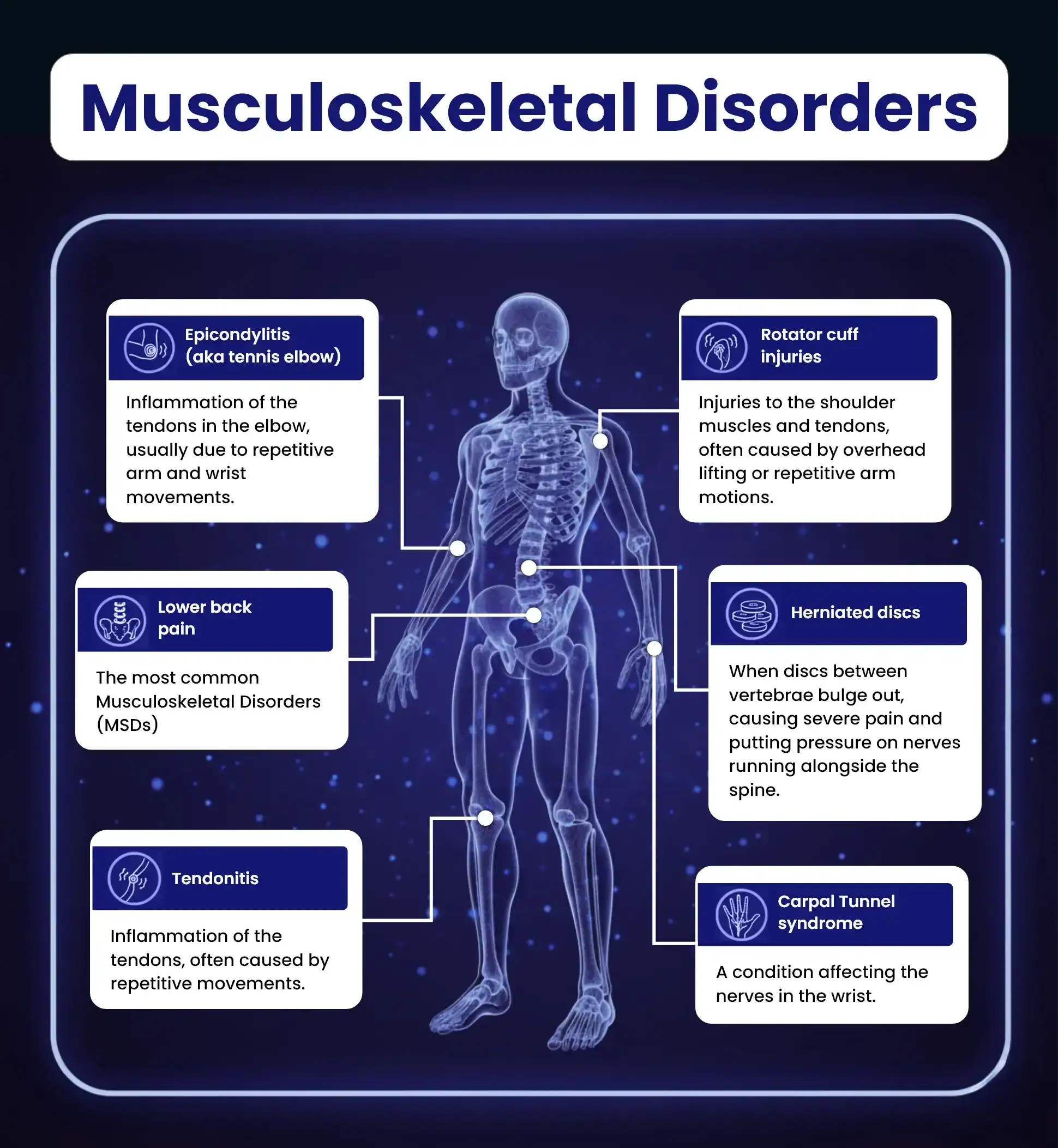

Musculoskeletal Disorders

The term “musculoskeletal disorder” can refer to a range of conditions affecting either the bones, joints, muscles, tendons or soft tissues.

While disorders vary, they all share two common symptoms: pain and limited movement.

Obviously, employees who suffer from MSDs struggle to be productive, both in and outside of work. They also often need a long time away from their jobs to recover. According to the NHS, musculoskeletal disorders lose 30 million working days every year in the UK.

Preventing musculoskeletal disorders can be challenging as they aren’t usually caused by one single event. Instead, they develop from repeated actions or prolonged exposure to certain conditions, such as working in awkward positions or spending long hours at a desk.

Manual Handling Training

Our Manual Handling training course helps users ensure that they are sufficiently trained in the principles and practices of safe manual handling to control and minimise manual handling-related injuries and to ensure a safe workplace for all.

Common Causes of Musculoskeletal Disorders

Understanding how to prevent musculoskeletal disorders in the workplace starts with an understanding of ergonomics.

Ergonomics is the science of designing work tasks, equipment and areas to fit the people who use them. The aim is to make work comfortable and prevent the awkward postures, repetitive movements and heavy lifts that cause musculoskeletal disorders.

Unfortunately, there are three common work scenarios where ergonomics is overlooked.

Exposure to Vibration

Using power tools or heavy machinery can expose workers to vibration.

Over time, vibrations can damage the nerves, muscles and joints in the hands, arms and shoulders. Hand-arm vibration syndrome (HAVS) is a common condition that can develop from prolonged exposure to vibrating equipment. It can lead to numbness, pain and even loss of function in the affected areas.

It’s mainly workers in construction or heavy industry who face vibration hazards. But you don’t have to work with your hands to be at risk of developing an MSD.

Working at a Desk

Workers who spend most of their time behind a desk can also develop MSDs.

Sitting for long periods can cause strain in the back, neck and shoulders. And if display screen equipment (such as a computer monitor, laptop, smartphone or tablet) is positioned incorrectly, workers might slouch or crane their necks while working.

Desk workers are also particularly vulnerable to upper limb disorders, a specific type of MSD. Upper limb disorders (USDs) can be caused by repetitive typing, using a mouse or maintaining awkward arm and wrist positions for extended periods.

USDs cause anything from mild discomfort to serious pain. In severe cases, they can lead to numbness or limited range of motion.

Manual Handling

Manual handling (the movement of a load by bodily force) is the most common cause of musculoskeletal disorders.

Although construction and industrial workers are most at risk, anyone may need to move something by hand in their workplace.

Lifting, carrying, pushing or pulling heavy loads can put significant strain on the body, particularly the back. Incorrect lifting techniques or awkward movements such as twisting or stooping further increase the risk of injury. Even lifting light objects can be dangerous if workers aren’t given opportunities to rest or vary movement patterns.

What the Law Says on Preventing Musculoskeletal Disorders

Under the Health and Safety at Work Act 1974, all employers have a duty to ensure the health, safety and welfare of their employees and prevent any work-related harm.

So, the law is clear: If your workers are at risk, you must take steps to prevent musculoskeletal disorders.

The first step is to complete a general risk assessment, as required by the Management of Health and Safety at Work Regulations 1999.

These regulations require employers to identify workplace hazards and implement necessary safety measures to eliminate or control found risks.

If your general risk assessment shows workers are vulnerable to MSDs, there are further regulations you must comply with, depending on the source of the hazard. We’ve covered the two most relevant regulations below.

The Health and Safety (Display Screen Equipment) Regulations 1992

If MSD risks are linked to the use of computers and other screen-based equipment, you must comply with the Health and Safety (Display Screen Equipment) Regulations 1992.

Under these regulations, employers must assess workstation set-ups and provide the necessary equipment, training and breaks to prevent MSDs.

The Manual Handling Operations Regulations 1992

If MSD risks are linked to lifting, carrying, pushing or pulling objects, you must comply with the Manual Handling Operations Regulations 1992.

Under these regulations, employers must risk assess manual handling tasks and implement control measures to protect workers from injury.

You must first eliminate manual handling tasks where possible. If elimination isn’t practical, you must instead take steps to reduce injury risks.

How to Prevent Musculoskeletal Disorders in the Workplace

Assess Risks

As mentioned, risk assessments are the first step in preventing MSDs at work.

Start by looking closely at your employees’ tasks. Are they frequently lifting heavy objects, working in awkward postures or repeating the same motions?

Follow up your observations with a conversation. Talk to your workers and ask for their input. They’ll be able to tell you more about the risks they face and suggest practical ways to manage them.

Assessment Tools

The Health and Safety Executive (HSE) offers a range of assessment tools to help you systematically evaluate the risks associated with manual handling, repetitive tasks and awkward postures.

These tools provide a structured way to identify problem areas and take appropriate action to reduce the likelihood of MSDs developing.

- Manual Handling Assessment Charts (MAC Tool) – The MAC tool is designed to identify and assess high-risk manual handling tasks.

- Assessment of Repetitive Tasks (ART Tool) – The ART tool is specifically aimed at assessing repetitive work involving the upper limbs, such as tasks performed on assembly lines or using hand tools.

- Risk Assessment of Pushing and Pulling (RAPP Tool) – The RAPP tool will help you identify and assess high-risk pushing and pulling tasks, whether carried out with equipment or entirely by hand.

- Vibration Exposure Calculator – This tool is used to assess the risks from exposure to vibration for workers using vibrating tools and machinery.

Manage Risks

Once you’ve assessed the risks of musculoskeletal disorders in your workplace, the next step is to implement control measures that match the level of risk identified.

Control measures must be tailored to the specific risks in your workplace, so it would be impossible to list all your options here. Instead, we’re outlining some of the most common control measures that can be applied to reduce the risk of MSDs.

Control Measures for DSE Use

- Redesign workstations to allow employees to maintain neutral postures and reduce strain.

- Encourage regular breaks to avoid long periods of sitting or performing repetitive tasks.

- Provide furniture and equipment designed with ergonomics in mind.

Control Measures for Manual Handling

- Provide mechanical aids, such as trolleys or hoists, to minimise manual handling.

- Adjust tool and equipment handles to reduce excessive force and improve grip.

- Rotate tasks among workers to prevent overuse of the same muscle groups.

- Reduce load sizes or split heavy items into smaller parts to make manual handling safer.

Provide Training

Workers are the ones vulnerable to MSDs. Without proper training, they may be unable to recognise the risks they face and apply control measures successfully.

Involving workers in the risk assessment helps with this, but you also have to provide training. In fact, training is considered so vital that it’s a fixture of almost all regulations.

Both the Manual Handling Operations Regulations and the Display Screen Equipment Regulations require employers to ensure workers are trained to recognise MSD risks and follow safe procedures.

Key Takeaways

- Musculoskeletal disorders (MSDs) develop over time and can result in serious long-term injuries, so preventing them is essential for maintaining workplace health and safety.

- You must assess and manage risks related to MSDs.

- Match control measures to the specific risks in your workplace.

- Provide training that ensures workers can recognise risks and follow safe practices to prevent MSDs.

Online Manual Handling Training

Preventing musculoskeletal disorders in your workplace requires a combination of risk assessments and training.

Our online Manual Handling Training course equips your workers with the skills and knowledge they need to carry out manual handling tasks safely and effectively.

It covers essential techniques for lifting, carrying and moving loads that reduce the risk of injury. It also highlights common mistakes that can lead to MSDs and teaches workers how to avoid them. By making this training part of your broader health and safety strategy, you can help create a safer, more productive work environment.