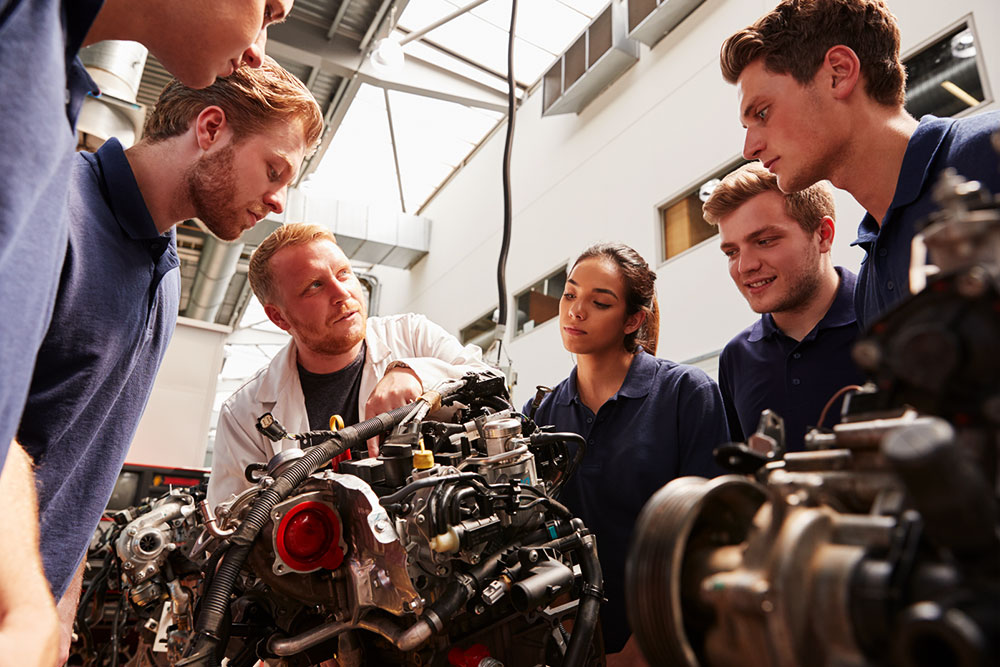

PUWER compliance can only be achieved when duty holders and the supporting cast recognise and apply best practice to their routine work. Our PUWER training courses have been designed with this fact in mind. Each programme is mapped to specific job roles to give users the exact training they need to fulfil their PUWER duties and ensure equipment safety.

Job-Aligned PUWER Training to Ensure Compliance Across Your Entire Organisation

Develops awareness of PUWER legislation and what it means for equipment users. This knowledge helps users recognise and flag non-compliance and ensures equipment is consistently operated in line with best practice.

Gives maintenance and support staff the understanding to square off PUWER inspection reports and resolve actions, keeping work equipment safe, compliant and ready for use every day. Support teams can also apply their PUWER knowledge in other routine maintenance tasks, giving you another set of trained eyes able to spot non-compliance.

Gain the skills needed to ensure equipment safety through effective team leadership and continuous learning. Users learn how effective supervisors promote an open reporting culture, develop their team’s technical expertise and implement proactive risk management strategies.

Develop the depth of knowledge needed to manage ongoing PUWER compliance across operations. Users gain a detailed understanding of the regulations, letting them oversee compliance within their organisation and ensure risk assessments and inspections are meeting expected standards. Content also includes guidance on appointing persons to take on PUWER duties as well as benchmarking and developing competency within teams.

Develop and prove the competency to perform PUWER inspections. This course combines online training and expert-verified practical assessments. Users complete eight theory modules giving them an understanding of compliant PUWER inspections before performing and recording an inspection of equipment within their own workplace. An independent assessor then reviews the inspection and verifies their competency, giving users conclusive evidence of their ability to inspect equipment in line with best practice.