Hazards and risks are two elements that are routinely confused. It is important to recognise the distinction, as a good understanding of them is essential to managing health and safety in the workplace.

An understanding of hazard and risk is fundamental when undertaking a risk assessment, which is the globally recognised system for managing risk.

Key Takeaways

- A hazard is something that could cause harm, such as a corrosive chemical or working at height. Risk is a calculation of the likelihood and severity of the harm caused by a hazard.

- In a risk assessment, hazards are first identified. Their corresponding risk is then calculated and appropriate control measures are determined.

- Anyone responsible for occupational health and safety must understand both the hazards and risks in their workplace.

- Training provides guidance on identifying hazards, assessing risks and implementing control measures.

Hazard vs. Risk in a Nutshell

Hazard and risk are often used interchangeably. But they have precise and distinct meanings in health and safety.

Hazard is something that can cause harm.

Risk is the likelihood and severity of harm caused by a hazard.

Every hazard has a risk associated with it. This risk can vary in different environments and situations. In workplace health and safety, a hazard is first identified, and then its associated level of risk is defined.

Employers must identify workplace hazards, assess the risks, and take measures to comply with the law.

What is a Hazard?

A hazard is something that has the potential to cause harm. Hazards are common in the workplace. They could be a vehicle, a piece of machinery, or a puddle of water. Anyone who works on-site should be aware of the various hazards. Recognising them and understanding how to control them could save lives.

For example, you could work in a warehouse where you are required to use ladders. Ladders are among the most common workplace hazards. Ladder safety training is necessary so you don’t cause yourself or others harm, or damage company property.

Types of Hazards

The categories of hazards are:

- Mechanical: Such as slipping, tripping or falling over obstacles such as debris on a building site.

- Hazardous Substances: These include substances that are poisonous, flammable or can damage the respiratory system if inhaled.

- Physical Hazards: These include pressure systems, drowning and manual handling, such as using a spade to dig a hole.

- Environment: These include temperature, asphyxiation and noise.

- Psychological: Such as stress and fatigue.

- Electrical: Objects that use electricity.

Risk Assessment Training

Our Risk Assessment Training provide vital information to recognise and eradicate a hazard that can cause harm within a workplace or an organisation. Risk assessment is the keystone of safety and health that helps identify and mitigate the possibility of such hazards to ensure safety for all.

How to Identify Hazards

Hazard identification is the first step in conducting a risk assessment, which is a legal requirement under the Management of Health and Safety at Work Regulations 1999. These regulations place a duty on employers to carry out suitable and sufficient risk assessments and to record the significant findings.

To identify hazards:

- Examine your workplace and observe how tasks are carried out

- Ask workers what they think might be unsafe

- Consider non-routine activities like cleaning or maintenance

- Review past accident reports and near-miss records

Hazards may come from physical equipment, substances used in tasks, how people interact with their environment, or even work-related stress and anxiety.

This process must be thorough. Any hazard that goes uncontrolled is a potential accident waiting to happen. You must be aware of every hazard in your workplace, the potential harm they could cause and who might be affected. This information is essential for assessing risk.

What is a Risk?

A risk is the likelihood that a hazard will cause harm, combined with the potential severity of that harm. For example, using a stepladder typically involves less risk than using an extension ladder, primarily due to the difference in working height. A fall from a greater height is more likely to result in serious injury.

Risk can be reduced by implementing safety measures or limiting exposure to hazards. Risk Assessments are used to evaluate the risks that hazards present and decide how best to avoid or limit them. Nobody should fear for their well-being whilst at work and most dangers in these environments can be avoided with the right evaluation of the risks.

Imagine a task that involves the use of a blow torch. The worker could burn themselves or set something on fire. But what is the likelihood of that happening? If they have been trained how to use it safely, the likelihood is low. But should they accidentally set something on fire, the person or their work colleagues could get seriously hurt, or property destroyed. The risk assessment could conclude that there is a low possibility of harm being caused, but a severe level of harm should an accident occur.

Whenever there is a foreseeable risk like this, employers have a duty to carry out a risk assessment under the Management of Health and Safety at Work Regulations (1999).

Types of Risks

Common types of risks include:

- Operational Risk: When hazards affect work performance or systems (e.g. machinery failures).

- Health Risk: Where exposure may lead to illness or injury (e.g. chemical inhalation).

- Safety Risk: Linked to accidents that could cause immediate physical harm (e.g. slips or falls).

- Environmental Risk: Where activities could cause harm to the environment (e.g. waste disposal).

- Psychosocial Risk: Related to stress, workload, or working conditions that harm mental health.

How Would a Risk be Evaluated?

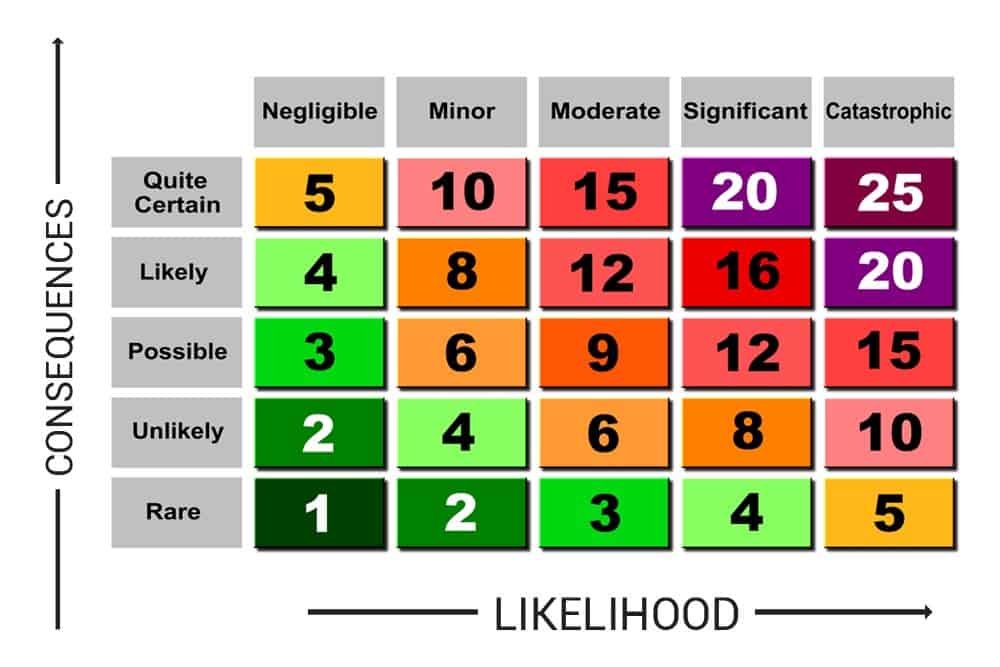

One way risk can be evaluated is through this 5×5 matrix:

This matrix compares the two aspects of risk.

On a score of 1 to 4 – the risk would be deemed as acceptable and no further action is required. Any existing controls should be maintained.

On a score of 5 to 9 – the risk is adequate and you can look to improve it if you can at the next review.

On a score of 10 to 16 – the risk is considered to be tolerable, but you need to look to improve it.

On a score of 17 to 25 – the risk is considered to be unacceptable. You need to halt work immediately and reduce the risk.

This matrix will not necessarily give you a hard and fast number. It’s an estimate that helps you decide where and how urgently precautions are needed.

How Do You Carry Out a Risk Assessment?

The Health and Safety Executive (HSE) prescribe five key areas to focus on when devising a risk assessment in a workplace:

1. What are the hazards?

- Consider the objects, activities and substances present and how they could harm those in proximity.

2. Who is at Risk?

- Consider who could be harmed by the hazards you have identified. This could be anyone from an employee to a customer.

- Consider the specific requirements of individuals, for example, if your processes produce a lot of smoke or fumes, asthmatics could be harmed more seriously than others.

3. How likely are the Risks?

- Consider the main risks that pose the biggest threat to general well-being.

4. Record Findings:

- Keep records of hazards, the harm they could cause and the methods used to control the risks.

5. Risk Assessment Review:

- Keep track of new or changing hazards as they present themselves.

Differences Between Hazards and Risks

Here are some key differences that clarify what is meant by hazard and risk:

| Hazard | Risk |

|---|---|

| Anything with the potential to cause harm | Likelihood that the hazard will cause harm, combined with the severity of that harm. |

| Static – it exists whether exposed or not | Dynamic – depends on exposure, conditions and controls |

| Examples: exposed wires, chemicals, noise | Examples: electric shock from a wire, poisoning, hearing loss |

| Identified first during assessments | Evaluated after identifying hazards |

| Must be eliminated where practical or controlled when elimination is not possible. | Reduced when hazards are eliminated or otherwise controlled. |

Controlling Risks

The hierarchy of controls outlines the most effective methods for reducing risk, ranked from most to least effective.

The goal is always to eliminate the hazard where possible. If elimination is not feasible, proceed down the hierarchy. In many cases, a combination of controls may be required to reduce risk to an acceptable level.

- Step 1: Elimination or substitution – Remove the hazard entirely or replace it with something less hazardous (e.g. use a safer substance or process).

- Step 2: Engineering controls – Modify equipment, workspaces or processes to reduce exposure (e.g. install barriers, guards or ventilation systems).

- Step 3: Administrative controls – Implement procedures that reduce risk through behaviour management (e.g. training, scheduling, cleaning, maintenance).

- Step 4: Personal protective equipment (PPE) – Use equipment such as gloves, masks or hearing protection to limit exposure when other controls are insufficient.

Hazard and Risk Training

For further information and guidance about how to carry out specific risk assessments, there are a variety of accredited training courses on the Human Focus website.

These are designed to advise managers and supervisors on a diverse range of risks in the workplace.