Look at any construction site and you’re sure to see massive heavy machinery at work. Backhoes, bulldozers, front loaders, cranes and graders all lumber about, moving vast amounts of dirt and debris. But what’s the exact purpose of each of these mammoth machines?

If you’re planning a construction career, you need to learn the different types of construction vehicles and what they’re used for. Our list of construction vehicles gives you all the info you need.

What Are Construction Vehicles?

Humans have been using giant machines to build complex structures for centuries. In the 1st century, an engineer called Vitruvius wrote about using heavy machinery and construction vehicles like cranes to build Roman roads and buildings. He doesn’t mention if they were yellow. (They probably weren’t, though.)

Nowadays, there isn’t a ‘one size fits all’ definition. ‘Heavy machinery’ is a catch-all to describe the powerful, immense machines used in construction, agriculture, mining and civil works.

Generally, any vehicle over two tonnes with a diesel engine that can’t be legally driven on the road is considered heavy machinery. They usually have a striking yellow paint job as well.

Construction vehicles can also be referred to as mobile plants. Don’t get confused here. The word ‘plant’ has nothing to do with gardening. We can thank the Romans again for that. It’s taken from the Latin word ‘plantare’, which means ‘to plant’ or ‘to drive into the ground.’

Whatever term you use to describe them, they are essential to any building project. Let’s look at some of the most common types of construction vehicles.

Construction Courses

Explore our range of online Construction Training courses. Designed to support compliance and safety during construction and in occupied buildings. Courses equip workers and duty holders with essential knowledge to work safely, efficiently and in line with industry standards.

Common Types of Construction Vehicles

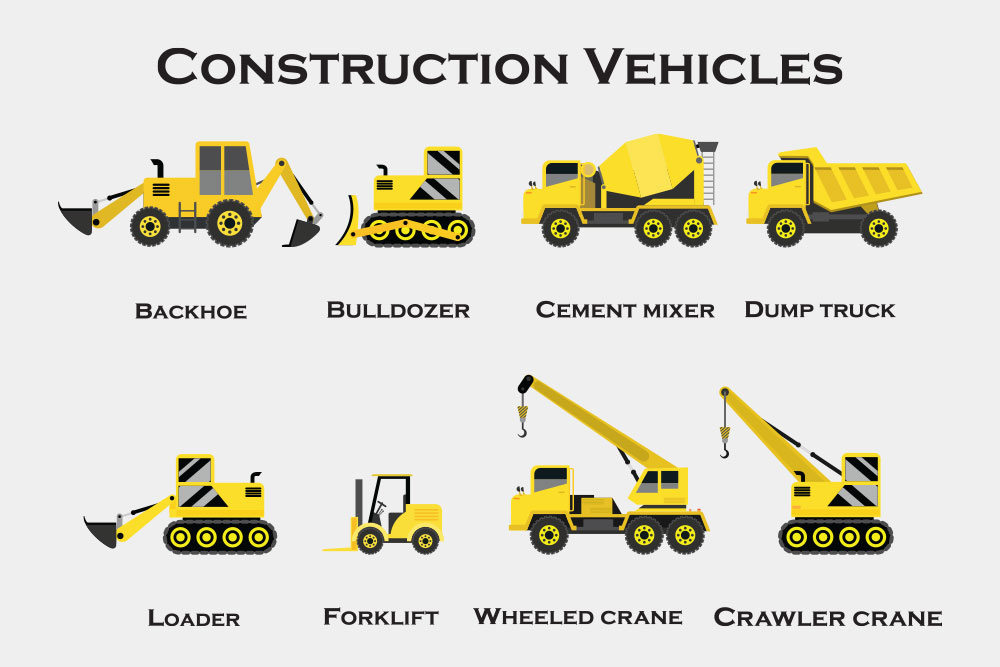

A modern construction site will be filled with vehicles of all shapes and sizes, each with a particular purpose. The list of construction vehicles below describes the heavy machinery you’re most likely to see. Almost all these vehicles will be used at some point during a construction project.

Bulldozers

When most people think of construction vehicles, a bulldozer is the first image that comes to mind. A bulldozer is a powerful tractor with a massive metal blade attached to the front. Hydraulic pistons raise and lower the metal blade. Bulldozers can have heavy-duty tyres or tracks. Bulldozers are used to move soil, sand and debris.

Backhoes

Sometimes called back actors or rear actors, backhoes are versatile vehicles found on almost every work site. Backhoes are relatively small, but they’re also incredibly useful. They can work in terrain that more oversized vehicles can’t access.

A backhoe has a small operator cab, a large loading bucket on the front of the vehicle, and a hoe fitted to the back – that’s where they got the name ‘backhoe’ from. Backhoes are used for digging trenches, excavation work, and clearing debris. They can also be used to put in fence posts and plant trees.

Concrete Mixer Trucks

Alongside the bulldozer, the concrete mixing truck is another construction vehicle familiar to most people. Concrete mixer trucks are standard trucks with a mixer drum attached to the back. The drum continuously spins to mix concrete, water, cement or other materials. It can be raised or lowered to empty its contents.

Dump Trucks

The dump truck does exactly what it says on the tin. A dump truck is used to carry loads of soil, sand or debris and, you guessed it, dump it somewhere else.

A dump truck will have oversized heavy-duty tyres and an open-box bed that can be raised and lowered via hydraulic rams. Dump trucks come in various sizes, from a normal-looking truck cab with a ‘bed’ on the back to the massive dump trucks used in the mining industry.

Front Loaders

Also called a front-end loader, bucket loader or scoop loader, these machines load materials into dump trucks or other areas in a building site. A loader can move gravel, dirt, debris and rocks quickly and easily.

Loaders have a small cab with a bucket at the front. They can have wheels or tracks. The bucket on a loader can be attached, or it may be able to be removed and replaced with forks.

Cranes

A favourite of old Vitruvius, cranes are one of the most important pieces of heavy machinery on a construction site. While they can be of various sizes, cranes usually have a small operator cab and a massive arm equipped with hydraulic pulleys and cables.

Cranes move heavy objects vertically or horizontally. Cranes can have tracks or wheels, or they can be stationary. Tower cranes are used when constructing larger buildings.

Graders

Equipped with long blades and heavy-duty wheels, graders aren’t used for marking school tests. A grader’s main job is to level out small amounts of debris from the ground so that foundations or roads can be laid. You’ll often see graders being used for civil works or road maintenance.

Compactors

Sometimes called drum rollers, compactors flatten uneven terrain in preparation for building work. Compactors have small cabs mounted on one or two large steel drum rollers.

Although they may not look exciting, compactors play a vital role in a construction project. Suppose the soil isn’t properly compacted before building work begins. In that case, issues like erosion, foundation cracks, and plumbing problems can occur.

Excavators

Excavation work is essential to a construction project. And obviously, the best way to do it is with an excavator.

An excavator will have a cab mounted on a moveable platform with a hydraulic boom arm, a dipper and a bucket. Excavators come in various sizes and are track powered, so they can cover rough terrain easily.

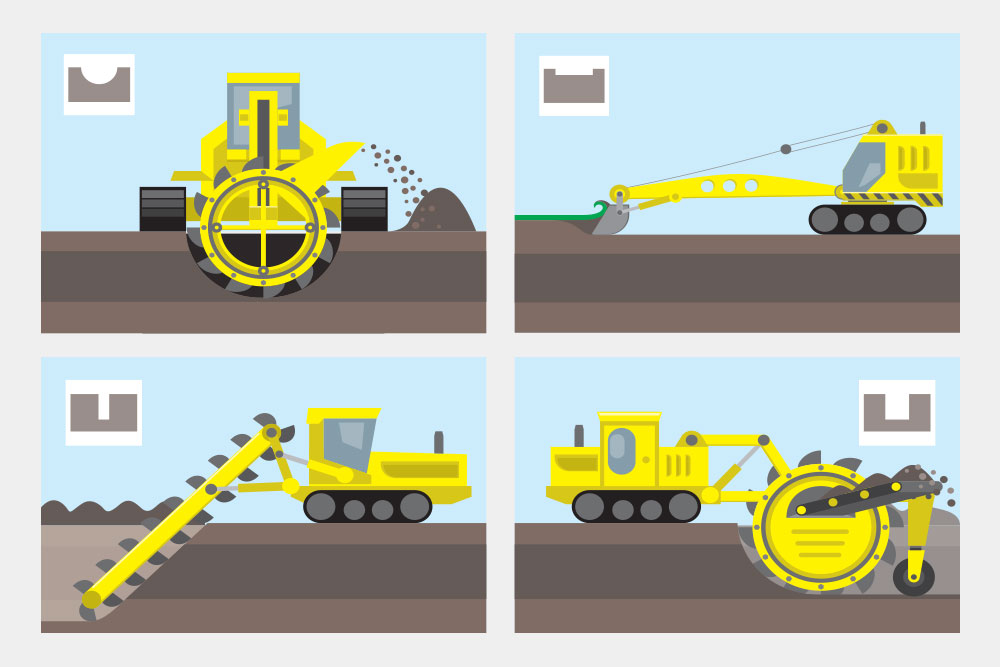

Trenchers

Trenchers are formidable-looking machines that come in various sizes and configurations. Trenchers can be walk-behind units, self-propelled or have a driver’s cab. They are equipped with digging chains or metal wheels used to dig trenches. As one might expect from the name.

Types of Construction Vehicles by Function

Construction vehicles are often grouped by the jobs they perform. This makes it easier to understand which machines are suited for which tasks on site. Below are the main functional categories:

Earthmoving Vehicles

Earthmoving vehicles are built to dig, push, lift or remove large amounts of soil, sand and rock. They prepare land for construction by shaping terrain, creating foundations, and clearing debris. Bulldozers, excavators, backhoes and graders fall into this group.

Material Handling Vehicles

These vehicles lift, carry and position heavy loads such as steel beams, pipes, concrete blocks or loose material. They make it possible to move items that would be impossible by hand. Cranes, front loaders and dump trucks are the main examples.

Roadwork and Surface Preparation Vehicles

This group of vehicles prepares ground and surfaces so that structures, roads or pavements can be laid safely. They compact soil, level surfaces and dig precise channels for utilities. Compactors, graders and trenchers are typical machines used.

Specialised Vehicles

Specialised vehicles perform narrow or technical roles that other machines can’t. They include concrete mixer trucks that keep concrete ready to pour, trenchers that dig narrow trenches for pipes or cables, and tower cranes designed for tall or complex builds.

Heavy Machinery and Health and Safety

All construction work needs to be conducted according to the below pieces of legislation:

- The Health and Safety at Work Act 1974

- The Management of Health and Safety at Work Regulations 1999

- The Construction (Design and Management) Regulations 2007

- The Work at Height Regulations 2005

- The Supply of Machinery (Safety) Regulations 1992

- The Provision and Use of Work Equipment Regulations 1998

Despite these regulations, construction sites are still hazardous places. More construction workers are killed every year than in any other UK industry, according to figures from the Health and Safety Executive (HSE).

Many fatalities on building sites are due to accidents involving construction vehicles. Most of the incidents occurred because of insufficient separation of pedestrians and vehicles. These accidents can be avoided with careful planning and strictly controlling vehicle operations.

Vehicles must be segregated from pedestrians and regularly inspected, serviced and maintained. Staff must be trained to operate heavy vehicles competently and identify and control potential hazards.

Risk Assessment For Construction Workers

As the HSE puts it, ‘Successful management of construction vehicle activities is based on the provision and maintenance of safe workplaces, safe vehicles, safe drivers and safe work practices.’ The HSE stresses that ‘risk assessment is an essential part of effective health and safety’ for construction workers.

Our Introduction To Risk Assessment In Construction training course teaches participants to identify risks and control hazards. This is critical knowledge for anyone that works in the construction industry. Signing up for this course will help you keep your work site safe, stay within the law, and help you keep your people safe. Together, we can act to lower the number of accidents involving construction vehicles in the UK.