The ISO 14001 standard helps organisations measure and improve the environmental impact of their operations.

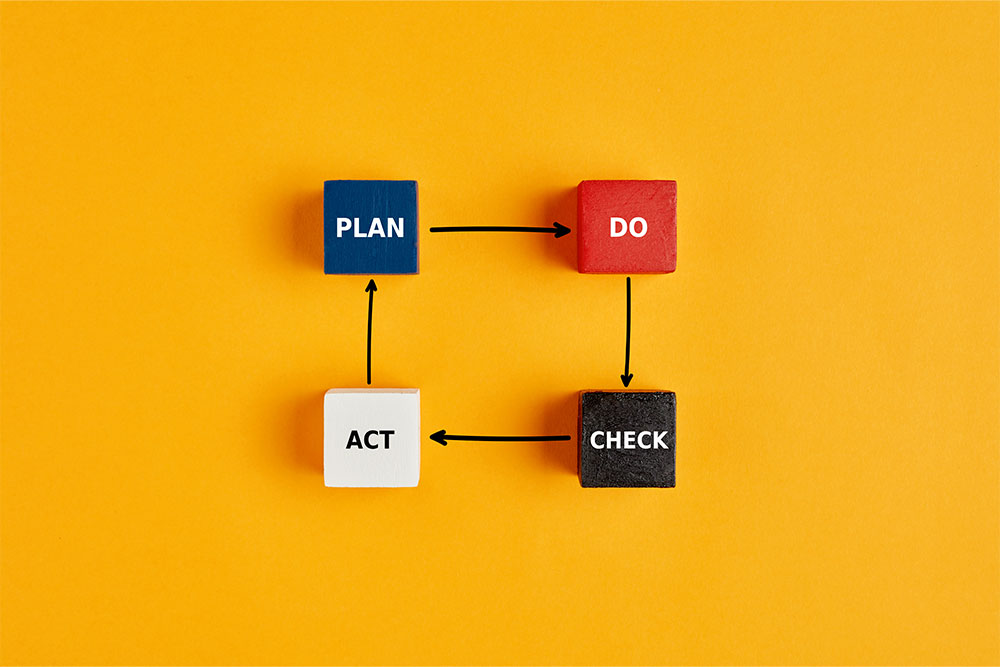

At the standard’s centre is the plan-do-check-act (PDCA) cycle, which helps organisations continuously improve their environmental management systems.

In this blog, we explain each stage of the cycle and how it’s implemented in ISO 14001.

Key Takeaways

- PDCA stands for plan, do, check, act.

- The PDCA cycle is at the core of ISO 14001 to help businesses continuously improve their environmental performance.

- The “plan” stage involves setting goals, understanding legal duties and identifying risks and opportunities.

- The “do” stage puts the plan into action through training, procedures and resource management.

- The “check” stage tracks performance, audits results and ensures legal compliance.

- The “act” stage focuses on fixing problems, adjusting plans and starting the next cycle for improvement.

- You can apply the PDCA cycle at all levels – across departments, individual projects or the entire organisation.

Understanding the Role of Plan-Do-Check-Act Cycle in ISO 14001

The PDCA cycle is a simple four-stage process: plan, do, check and act.

Each stage has a clear purpose, and together they form a loop. Once you finish one cycle, you start again – but with better knowledge and improvements from the last round.

You’ll find the PDCA cycle in other ISO standards, like quality management and health and safety. But in ISO 14001, it’s at the heart of how an environmental management system (EMS) works. It guides how organisations plan, act, review and improve their environmental efforts.

Let’s look at each stage of the cycle.

1. Plan

In the first stage, you plan what you want to achieve and how to get there. This means you will have to:

- Recognise how your business operations affect the environment

- Measure your environmental impacts, such as emissions, waste and energy use

- Set clear objectives and targets to improve your environmental performance

You also need to:

- Identify legal and regulatory requirements

- Look at risks and opportunities

- Define the scope of your EMS (which areas of your business it will cover)

For example, if your goal is to cut energy use by 10% in one year, your plan should explain how you’ll do that – maybe by upgrading equipment or changing work practices.

Health and Safety Courses

Our health and safety courses support legal compliance and effective risk management. They raise awareness of common workplace hazards and teach the fundamentals of safe working.

2. Do

The “do” stage is about carrying out the work and maintaining control. It turns intentions into actions and ensures the system is actively being followed across the organisation.

In this stage, you:

- Allocate resources

- Manage documentation

- Train staff

- Roll out new procedures

This stage also covers emergency preparedness, like having a plan for chemical spills or equipment failure.

The goal is to keep control of the process and make sure your EMS is more than just words on paper.

3. Check

After the plan is implemented, the next step is to “check” its impact. Here, you measure how things are going and where you can do better.

Are you meeting your goals? Are you following the plan? Are you staying compliant?

You do this by collecting data on current energy use, waste, emissions or any other areas in which you’re attempting to make progress. Results can then be compared against your targets for a measure of success.

You also carry out internal audits and check compliance with laws. If something’s off track, this is where you catch it.

4. Act

Next, you “act” on what you learned in the previous stage.

If goals weren’t met, you figure out why and adjust your approach. You might need to change how you do things, retrain staff or set new objectives.

Senior management should also review the system here to verify it’s still suitable and aligned with business goals.

This step completes the cycle and starts the next one. Every action feeds into a new plan, starting the cycle again. This is how the system improves over time. Instead of standing still, the organisation learns from each cycle and becomes more efficient and compliant with every round.

Why the Plan-Do-Check-Act Cycle Matters in ISO 14001

The plan-do-check-act cycle is foundational to the ISO 14001 framework. It helps turn intentions into action and makes continuous improvement possible.

This approach has several other benefits:

- Supports better performance by regularly checking and adjusting processes that affect the environment.

- Helps meet legal duties by tracking compliance with environmental laws and correcting any gaps.

- Builds a culture of responsibility by making sure everyone knows their role and follows through.

- Gives flexibility to respond to change like new laws, risks or business activities, without losing control of the system.

Using the PDCA Cycle at Different Levels

The PDCA model isn’t just used across the entire organisation. It can be applied to individual departments, specific processes or short-term projects.

For example, if your company is introducing a new waste recycling system, you can apply the PDCA cycle just to that project. It would allow you to plan the system, train staff, roll it out, measure results and then act on any issues.

This flexibility is one of the model’s strengths. It gives structure to all kinds of improvements, whether they’re big or small. It also helps embed environmental thinking into all areas of the business.

Common Pitfalls

While the PDCA cycle is simple, some organisations make mistakes when using it.

Rushing Stages

Senior leaders may rush to plan and implement changes, seeking rapid improvements. This issue can stem from a critical misunderstanding of the cycle, where equal weighting isn’t given to each stage. It’s important to recognise that without feedback loops, progress will be limited. You must have systems in place to “check” that your new procedures are working, and then “act” on that information in the next cycle.

No Senior Support

A lack of immediate improvement can also cause senior leaders to withdraw support. The PDCA cycle works best when there’s clear leadership and resourcing through all stages. Explain that objectives won’t necessarily be met all at once and that the PDCA cycle is designed for ongoing development.

Not Engaging Employees

A lack of participation from workers also hurts progress. If staff aren’t trained or involved, they may resist changes. Without input and effort from the frontline, your EMS won’t function as hoped. You’ll also lose a valuable source of insight into its performance for the “check” and “act” stages.

Training Makes the Difference

Many organisations struggle to implement the ISO 14001 standard because their teams don’t understand it. Training helps address this issue. It gives frontline staff the necessary awareness of ISO 14001 and its framework for environmental management.

In fact, this awareness is so critical that it’s required under Clause 7 of the standard.

Our online course offers a clear introduction to the ISO 14001 standard, its core requirements and the PDCA cycle that drives it. It provides an overview of environmental management and helps workers understand and engage with the EMS.

Enrol now to understand ISO 14001 and how to put the PDCA cycle into action.