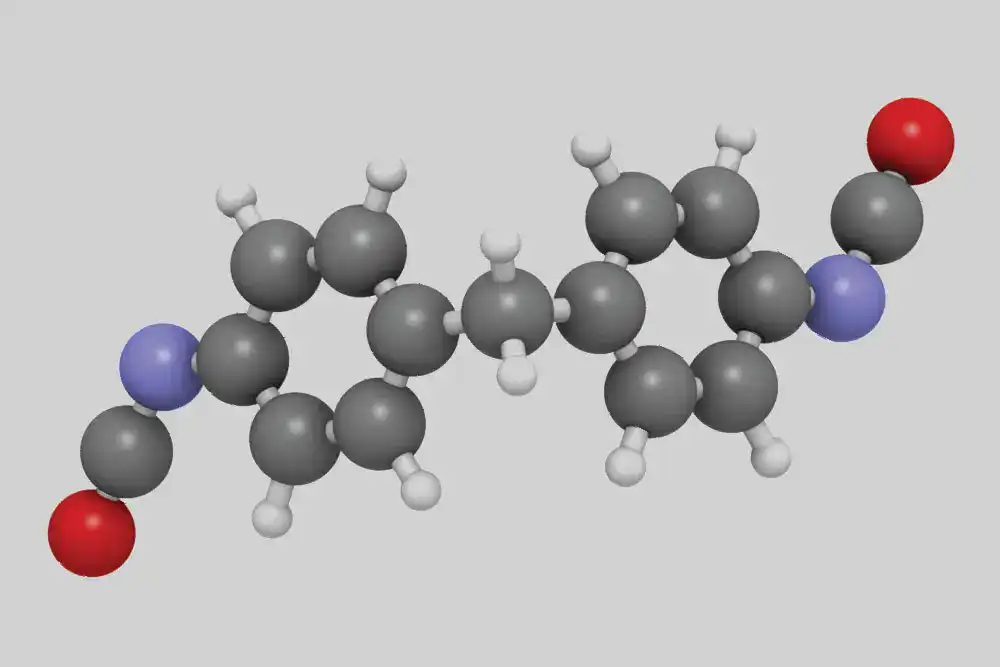

Chronic exposure to diisocyanates may lead to severe conditions such as asthma, hypersensitivity pneumonitis and cancer. In extreme cases, exposure may even prove to be fatal. To prevent these risks, managers must know how to supervise the proper handling of diisocyanates. They must also ensure that all employees undertake training to use diisocyanates and follow safety guidelines.

This training programme equips managers with the knowledge and skills to identify exposure risks, mitigate health hazards and implement control measures to ensure a safe working environment for their employees. Managers learn how to reduce the potential risks associated with diisocyanates, protect the health of employees and ensure operations run without incident or delay.

Are You Aware of Your Legal Responsibilities?

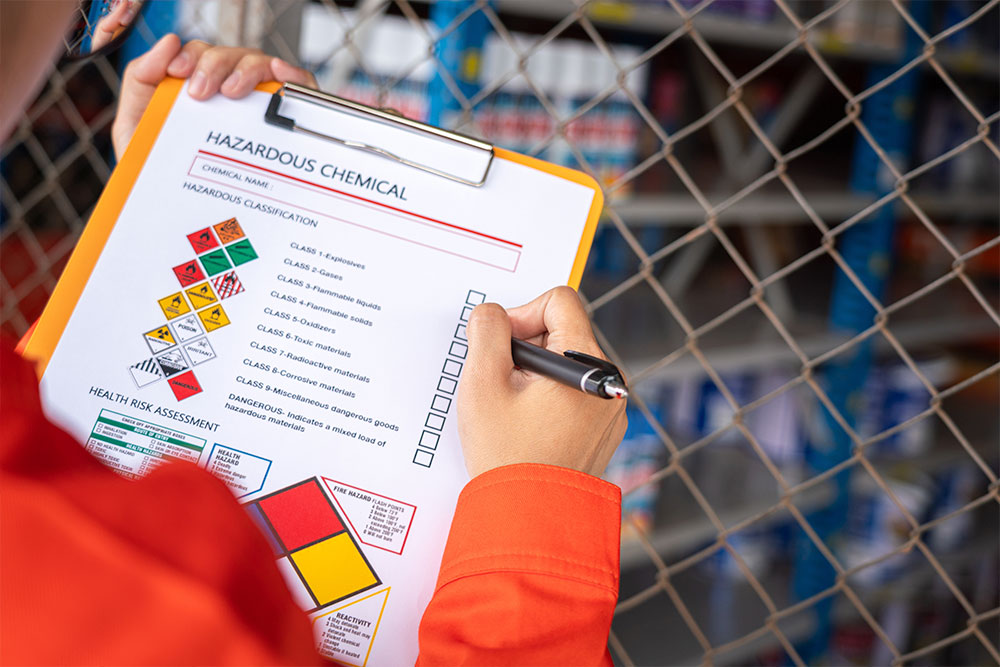

The UK regulation on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) makes diisocyanates training mandatory for all professional and industrial employees handling or using products containing more than 0.1% monomeric diisocyanates.

As a manager, it is your legal responsibility to ensure that all employees at risk of diisocyanate exposure receive training for safe diisocyanate use and handling. You are also responsible for implementing safety measures and ensuring all regulatory requirements are met.

In addition to REACH, you must also act in accordance with the following legislation:

- Health and Safety at Work Act (HSWA) 1974

- Management of Health and Safety at Work Regulations (MHSWR) 1999

- Control of Substances Hazardous to Health Regulations (COSHH) 2002

- Classification, Labelling, and Packaging (CLP) Regulation 2008

Non-compliance can lead to severe consequences, including fines, penalties, criminal charges and operational disruptions due to enforcement actions.

About Diisocyanates Training for Managers

Diisocyanates can pose substantial health and safety risks when not handled properly. This training programme helps managers and supervisors keep operations safe and protect employees working with diisocyanates from the risks of exposure.

The course explains diisocyanates, including their properties, applications and potential hazards. It also covers legislation surrounding diisocyanate use. This knowledge will allow managers to safely supervise activities involving diisocyanates, implement effective control measures and respond appropriately should an incident happen.

Managers who complete the course will fulfil the requirements for training under UK REACH regulations.