If you’re responsible for health and safety at work, you’ve probably come across Heinrich’s Triangle. It’s one of the most widely cited models in incident prevention – even now, almost a century after it was first proposed.

But what should you take away from it? And, more importantly, is it still relevant today?

This blog explains what Heinrich’s Triangle is, how it’s been updated over the years and what these models can actually teach you about preventing serious workplace accidents.

Key Takeaways

- Heinrich’s Triangle is a well-known safety model that suggests a relationship between minor and major incidents. Heinrich believed that reducing minor incidents would also reduce the likelihood of serious accidents.

- Bird’s Triangle is an updated version of the model. It incorporates near misses and property damage.

- The triangle is helpful in raising awareness, but has clear limitations. It simplifies accident causation and may overlook deeper system-level issues.

- Modern safety management focuses on incident investigation, root cause analysis and systems-based thinking – approaches that address the actual drivers of serious harm.

What Is Heinrich’s Triangle?

Heinrich’s Triangle was introduced in the 1930s by Herbert Heinrich, an American industrial safety pioneer. As part of his work for insurance provider Travelers, he reviewed around 75,000 industrial incident reports in an attempt to understand how workplace accidents happen.

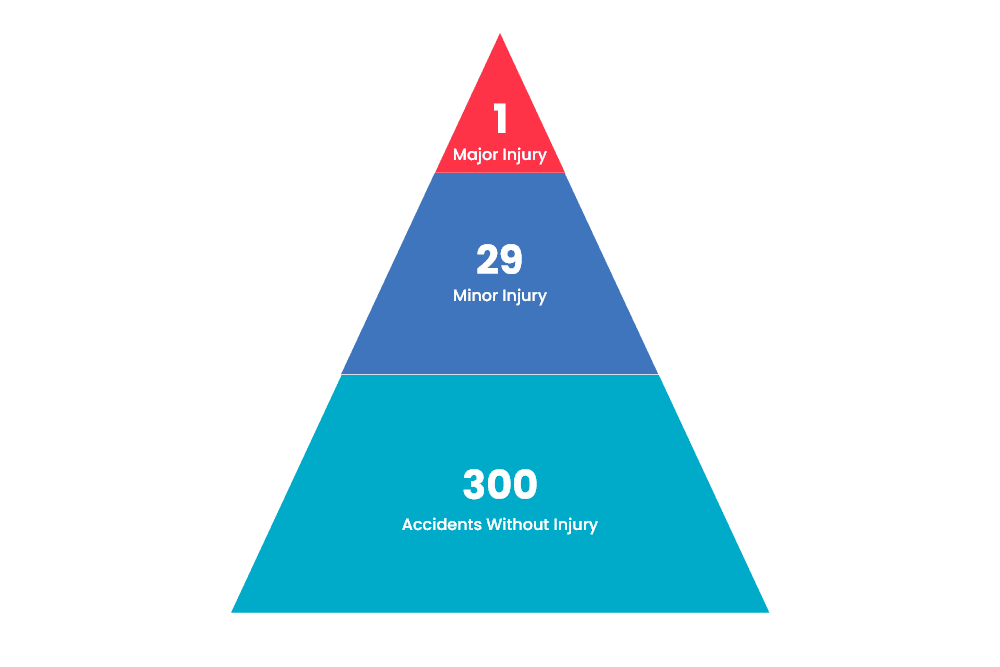

Based on his analysis, he proposed a simple ratio to illustrate how accidents are related:

1 major injury : 29 minor injuries : 300 no-injury incidents

Heinrich concluded that serious accidents don’t happen in isolation. They’re preceded by hundreds of smaller incidents and unsafe acts that go unnoticed or unaddressed.

This thinking suggests that if you can reduce the number of minor incidents, you also reduce the likelihood of a major injury. Heinrich was one of the first to promote proactive safety management – the idea that tackling small problems now can help prevent serious harm later.

However, Heinrich’s Triangle doesn’t conclude that every 300 no-injury incidents will lead to a serious accident. It’s not a prediction tool.

Instead, it’s a visual guide to help employers understand how problems accumulate over time and why addressing near misses and low-level hazards is more important than it seems.

Health and Safety Courses

Our health and safety courses support legal compliance and effective risk management. They raise awareness of common workplace hazards and teach the fundamentals of safe working.

What Is Bird’s Triangle?

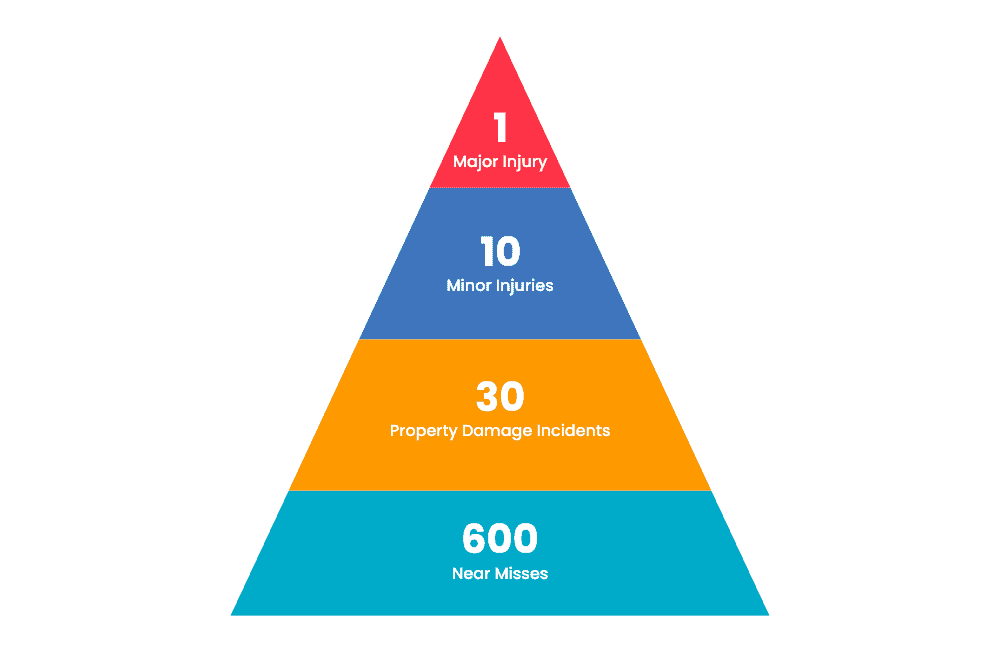

In 1969, safety consultant Frank Bird expanded on Heinrich’s work using a much larger dataset.

After analysing over 1.7 million incident reports across multiple industries, he proposed a new version of the accident triangle, which became known as Bird’s Triangle.

The revised ratio was:

1 major injury : 10 minor injuries : 30 property damage incidents : 600 near misses

Bird’s model was significant because it introduced two new elements:

- Near misses – incidents where the conditions for harm existed but people and property escaped unscathed

- Property damage – incidents that cause material loss, even if no one is injured

Bird emphasised the value of investigating all types of unplanned events, not just those involving harm. This thinking laid the groundwork for modern systems that recognise property damage and near misses as reliable indicators of wider safety issues, alongside minor accidents and injuries.

Like Heinrich’s, Bird’s Triangle isn’t a predictive formula. But it reinforces the same idea: the path to serious accidents is often paved with minor incidents.

Other Versions of the Safety Triangle

Since Heinrich and Bird introduced their models, many industries have created their own versions of the safety triangle (sometimes called the accident triangle or safety pyramid).

Some versions expand the triangle further to include unsafe conditions or behaviours at the very base. Others adjust the numbers based on internal data or specific industry risks. For example, high-risk sectors like construction may track thousands of near misses and hazard observations for every serious accident.

The key point is that none of these triangles are exact formulas. They’re general models used to illustrate a principle: investigating low-level incidents and unsafe events helps prevent serious harm.

How Is Heinrich’s Triangle Used Today?

Despite its age, you’ll still see Heinrich’s Triangle used in workplaces today.

In most cases, the triangle serves as a communication tool. It helps people understand the link between everyday incidents and serious accidents. This encourages the idea that no incident is too small to report, and that preventing harm means starting early.

Some organisations use the triangle as:

- A talking point during training or toolbox talks

- A visual aid in safety briefings

- A prompt for reporting minor incidents and unsafe conditions

- A way to support engagement with hazard spotting or behavioural observations

The simplicity of the triangle is part of its strength. It offers a memorable way to convey a core safety message: small issues are worth taking seriously.

But while the triangle remains a useful communication tool, it’s not without limitations. To understand how far its value really goes, it’s important to revisit where the idea came from.

Is Heinrich’s Triangle Still Useful Today?

Heinrich’s Triangle was widely accepted by thinkers and leaders of the time, and the concept shaped health and safety management for decades. It arguably still does.

However, there are some valid doubts about both Heinrich’s methodology and the lasting value of his conclusions.

Firstly, Heinrich studied a relatively small number of incidents in one sector (manufacturing) and based his analysis on accident reports written by supervisors. From these sources alone, it was impossible for Heinrich to draw any sweeping conclusions regarding workplace safety.

Secondly, his interpretations were arguably biased. While he was a pioneer, Heinrich’s work was a product of 1930s thinking. At the time, workplace accidents were often blamed squarely on worker behaviour. Heinrich did nothing to challenge this belief. In fact, he actively promoted it .

Finally, critics caution against taking the triangle too literally. While any safety improvements are worthwhile, focusing on minor incidents can create a false sense of control. It’s now widely accepted that any unplanned event should be investigated. It’s highly likely that the same root cause of a minor incident will eventually lead to a major one.

But while these concerns are all valid, the core idea remains useful: Most serious incidents are preceded by warning signs. Minor incidents are opportunities to intervene.

What’s a Better Way to Think About Accident Prevention?

If Heinrich’s Triangle can’t realistically be used to prevent accidents, what can?

Modern accident prevention models focus less on counting incident types and more on understanding how and why things go wrong. Two widely used approaches are the Swiss Cheese Model and AcciMap.

- The Swiss Cheese Model, developed by James Reason, shows how accidents happen when multiple system failures align. Imagine each safeguard in your workplace as a slice of swiss cheese. Each slice inevitably has holes, i.e., weaknesses. If these “holes” line up, an accident happens. The model helps teams understand that accidents are the result of overlapping failures – not a single root cause, as Heinrich believed.

- AcciMap, developed by Jens Rasmussen, is a systems-based approach that maps out the wider conditions behind an incident. Rather than blaming frontline behaviour, it looks at contributing factors across levels – from equipment and procedures to organisational culture and regulation.

These models shift the focus away from the individual and toward the broader system. They ask: What made the unsafe act possible? What allowed the warning signs to go unnoticed? It’s this kind of thinking that enables true accident prevention.

Want to Prevent Accidents in Your Workplace?

If you’re exploring Heinrich’s Triangle, you’re likely looking for practical ways to prevent serious incidents, not just theories. The next step is understanding how to investigate incidents properly and learn the right lessons.

Accident Investigation Training

This CPD-certified course introduces the core principles of accident and incident investigation. It’s ideal for anyone responsible for reporting, recording or responding to unplanned events.

You’ll learn how to identify root causes, gather evidence and suggest meaningful safety improvements, not just assign blame.

Near Miss Reporting for Effective Learning

If you already have investigation processes in place but aren’t seeing significant improvements in safety, you need this advanced course.

Created by Ian Pemberton, Human Focus’ Managing Director, it’s designed for safety managers, senior leaders, and anyone who’s serious about making their workplace safer.

The course offers a comprehensive guide to using near miss reporting as a foundation for meaningful learning and lasting improvement.

You’ll discover how to:

- Investigate near misses with the same rigour as actual accidents

- Build trust and psychological safety to encourage consistent reporting

- Design systems that capture and act on early warning signs

This course goes far beyond investigation. It’s about shifting your workplace from compliance-led reporting to a learning-first culture that stops harm before it happens.